In the realm of fastening and securing cables, wires, and other objects, nylon cable ties stand out as a ubiquitous solution. However, what many may not realize is that within this seemingly simple tool lies a diversity of options tailored to various needs and applications. From standard to heavy-duty, UV-resistant to heat-stabilized, the world of nylon cable ties offers a spectrum of choices designed to meet specific requirements.

Standard nylon cable ties are the most common type, widely used for bundling wires, cables, and other items in both industrial and household settings. These ties are typically made from nylon 6/6, a material known for its strength, durability, and resistance to various environmental factors such as moisture and chemicals. They come in various lengths and widths, allowing for flexibility in securing different-sized bundles.

For applications demanding extra strength and durability, heavy-duty nylon cable ties are the go-to choice. Constructed from thicker and stronger nylon materials, these ties can withstand higher tensile loads and offer enhanced resistance to abrasion and impact. They are ideal for securing heavy cables, hoses, and other items in demanding environments such as construction sites or manufacturing facilities.

In outdoor or harsh environments where exposure to sunlight can degrade traditional nylon ties, UV-resistant cable ties provide a solution. These ties are formulated with additives that protect them from the harmful effects of ultraviolet radiation, preventing premature degradation and ensuring long-term reliability. They are commonly used in outdoor installations, telecommunications infrastructure, and automotive applications where exposure to sunlight is inevitable.

Featured content:10 Questions You Should Know about Honeycomb Padded Envelope MailerHow to Choose Kraft Rigid Mailers10 Questions You Should Know about Custom Honeycomb Paper SleeveHow Does Recycled Paper Packaging Work?Custom Printed Kraft Self-Seal Padded Mailers: vs Plain Bubble MailersDiscover the Benefits of 70g Yogurt CupsKey Questions to Ask When Ordering Square Buckets with LidsAnother specialized variant is heat-stabilized nylon cable ties, designed to withstand high temperatures without losing their integrity. These ties are formulated with additives that enhance their heat resistance, allowing them to maintain their strength and functionality even in extreme heat conditions. They are often used in automotive, aerospace, and industrial applications where exposure to heat is a concern.

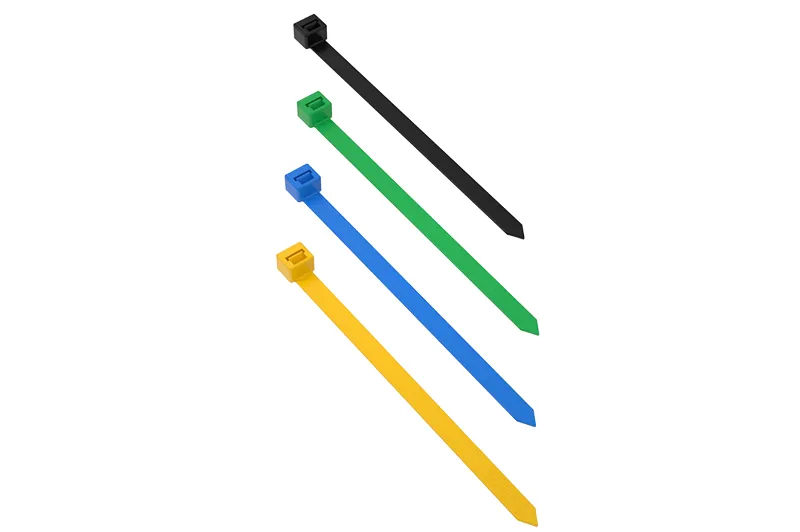

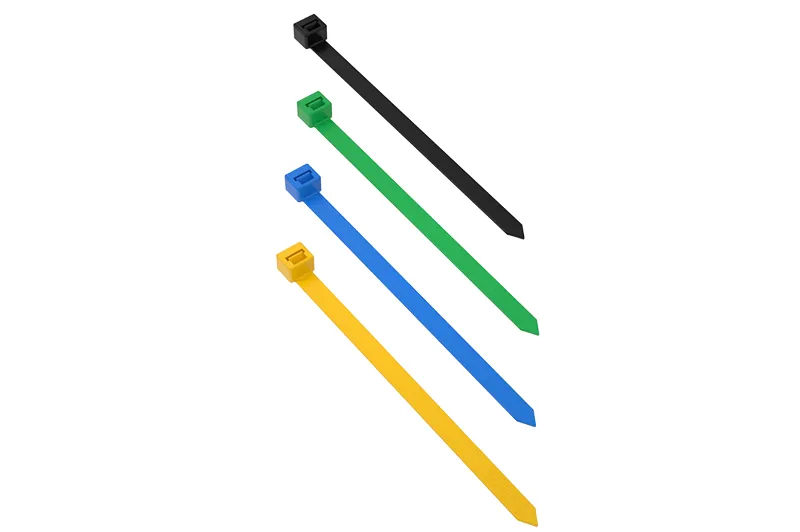

For applications requiring easy identification or color coding, colored nylon cable ties offer a practical solution. Available in a wide range of colors, these ties allow for quick visual identification of bundled items or specific components in complex systems. They are commonly used in electrical installations, network cabling, and organizing inventory in warehouses or storage facilities.

In addition to these specialized types, nylon zip ties also come in various designs to suit specific installation requirements. For instance, releasable cable ties feature a mechanism that allows them to be released and reused multiple times, making them ideal for temporary installations or situations where frequent adjustments are necessary. Meanwhile, push mount cable ties feature a mounting base that can be easily secured to surfaces using screws or adhesive, providing a convenient solution for securing cables to walls, ceilings, or other structures.

In conclusion, the world of ZGS nylon cable ties is far more diverse than meets the eye. From standard to heavy-duty, UV-resistant to heat-stabilized, and with various designs and colors to choose from, there's a nylon cable tie for virtually every application. By understanding the different types available and their respective features, users can select the most suitable option to meet their specific needs, ensuring secure and reliable cable management solutions.

Featured content:How Does Biodegradable Packaging for Organic Snacks Work?100 Pcs Resealable Bags,4.3" x 6.7"Clear Stand Up Food ...Top Choice: Eco-Friendly Fully Sustainable Padded Mailers4 Advice to Choose a Kraft Self Seal Padded MailerHow to Choose Custom Bag in Box? A Comprehensive GuideCustom Printed Paper Bags - Wholesale Takeout BagsWhy Choose 100% Kraft Paper Honeycomb Envelopes?

Comments

Please Join Us to post.

0