If you are looking for more details, kindly visit Suntex Electronics.

How to Choose Robotic Wire Harness AssemblyRobotic Wire Harness Assembly: A Guide for Beginners.

If you're looking for the best way to streamline your wire harnessing process, robotic wire harness assembly might be the solution. Robotic wire harness assembly has many benefits, including increased efficiency, reduced labor costs, and improved consistency in quality. But, if you're new to the world of robotic wire harness assembly, choosing the right one can be a daunting task. Here is a guide to help you choose the best robotic wire harness assembly for your business needs.

Performance.

One of the most important factors to consider when choosing a robotic wire harness assembly system is the performance. The system should have an excellent track record of performance and be able to meet your production requirements. It should be able to handle your wire harnesses' size and shape and perform the necessary operations with minimal errors. Ensure you ascertain the capacity of the robotic wire harness assembly system from the supplier before making a purchase.

Ease of Use.

The robotic wire harness assembly system you choose should be user-friendly and easy to use. It should be easy to program and modify, and the user interface should be easy to navigate. This will ensure that your employees can use it without difficulties and boost the overall efficiency of your wire harnessing process. Therefore, consider a system that comes with an easy-to-understand manual or guide.

Flexibility.

Another essential factor to consider is the flexibility of the robotic wire harness assembly system. Ensure that it can handle varying wire harness types, connectors, and accessories, and can be easily programmed and reconfigured to perform different assembly operations. A flexible system guarantees that you can accommodate variations in production without compromising the quality or efficiency of wire harness assembly.

Featured content:Strong Benefits To Vendor Independent Service ProvisioningThe difference between PCB multi-layer circuit board V cut ...How Does the Precision and Efficiency of a Lithium Battery Laser Welding Machine Improve Manufacturing Processes?Understanding the Benefits of Solar Emergency Charging LampsIs TFT display better than LED?Key Features and Benefits of Multi-angle Pole BaseExploring the Different Types of Transformers: A Comprehensive GuideCost.

When choosing a robotic wire harness assembly system, cost is an important factor to consider. The cost of the system should be within your budget and should be worth the investment. Select a system that guarantees to help you achieve your production and manufacturing goals. Moreover, ensure that you get a system with an affordable and reliable supply of spare parts and technical support from the manufacturer.

Quality.

Quality should always be a top priority when selecting a robotic wire harness assembly system. Ensure that the system’s quality of work meets your manufacturing requirements and that wire harnesses are assembled to the highest standards. Moreover, ensure that the robotic wire harness assembly system meets relevant industry standards and regulations.

Conclusion.

Robotic wire harness assembly is an efficient and reliable solution for any business looking to streamline their wire harnessing process. When choosing a robotic wire harness assembly system, it's essential to consider performance, flexibility, ease of use, cost, and quality. A system that meets these requirements will improve your manufacturing process's efficiency and help you meet your business's goals. .

If you have any questions or need more information, please don't hesitate to contact us for any assistance.

If you are looking for more details, kindly visit our website.

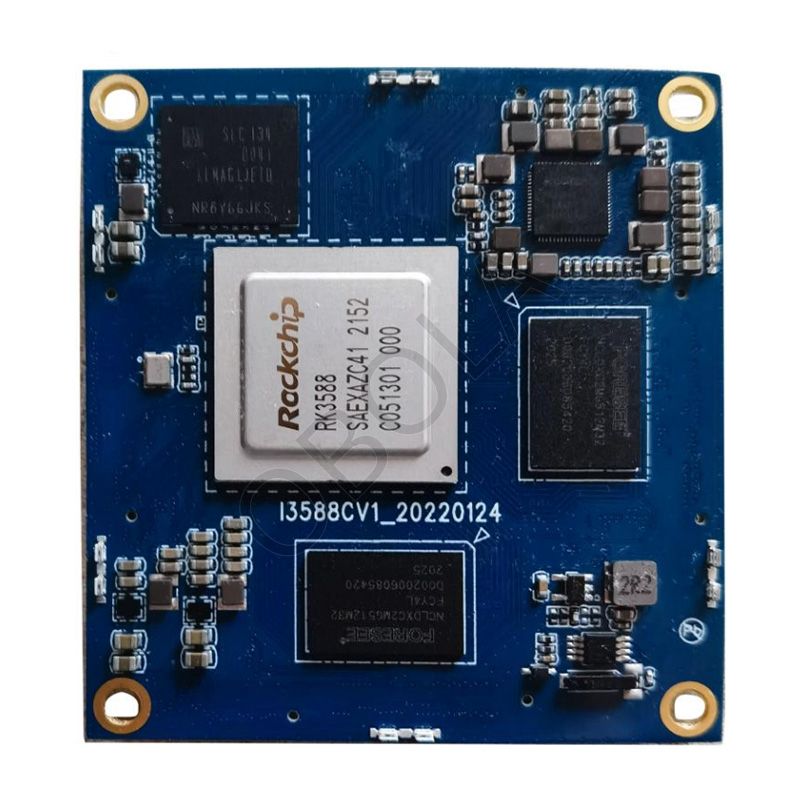

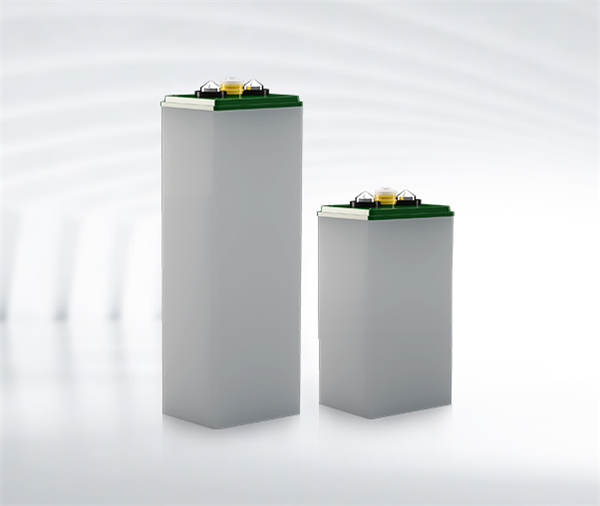

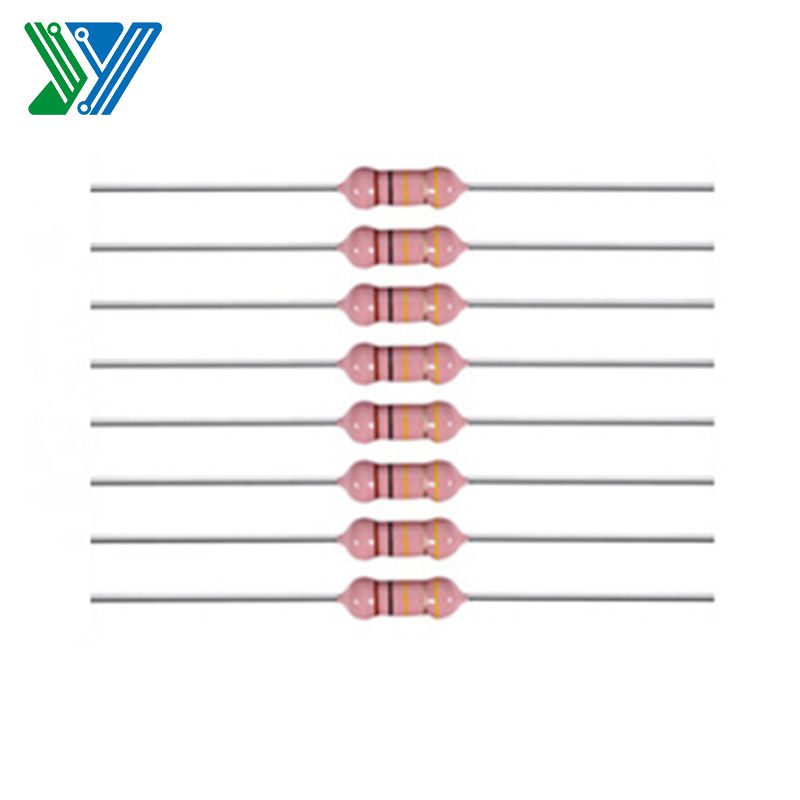

Featured content:Industries Benefiting from Power Resistors: Essential Components in Various ApplicationsUnveiling the Power of SOM Core Boards: Revolutionizing Your ElectronicsWhen to Consider Using an Emergency Power Pack for Reliable Power SupplyExploring the Benefits of Portable Power Stations: Reliable Power AnywhereHow does an electric under blanket work, and is it safe to use?Harnessing the Power of Artificial Intelligence PCBA: A New Era in ElectronicsKey Features and Functionalities of LCD Module

Comments

Please Join Us to post.

0