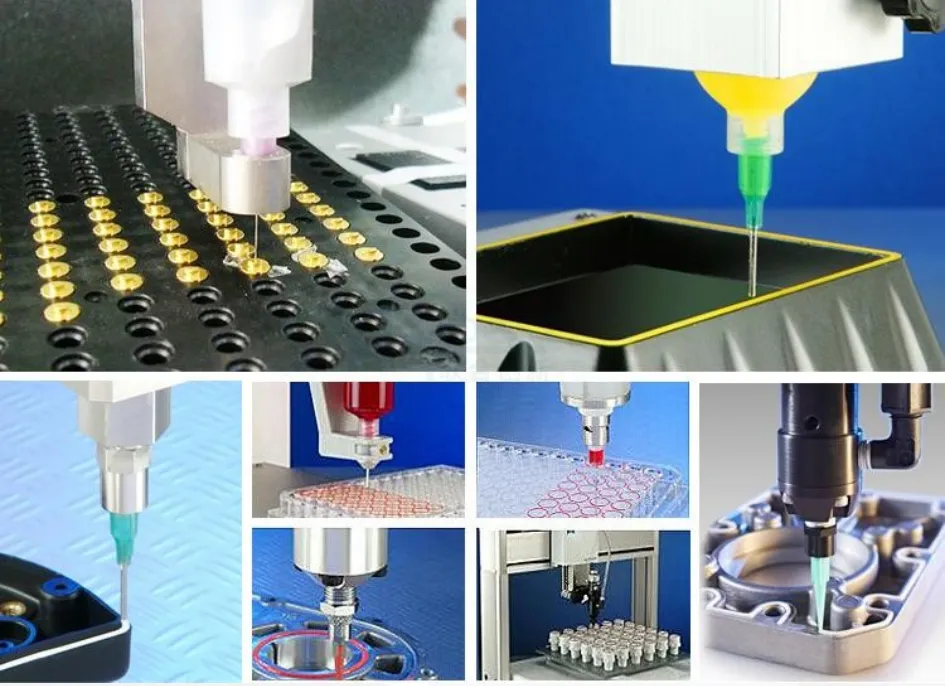

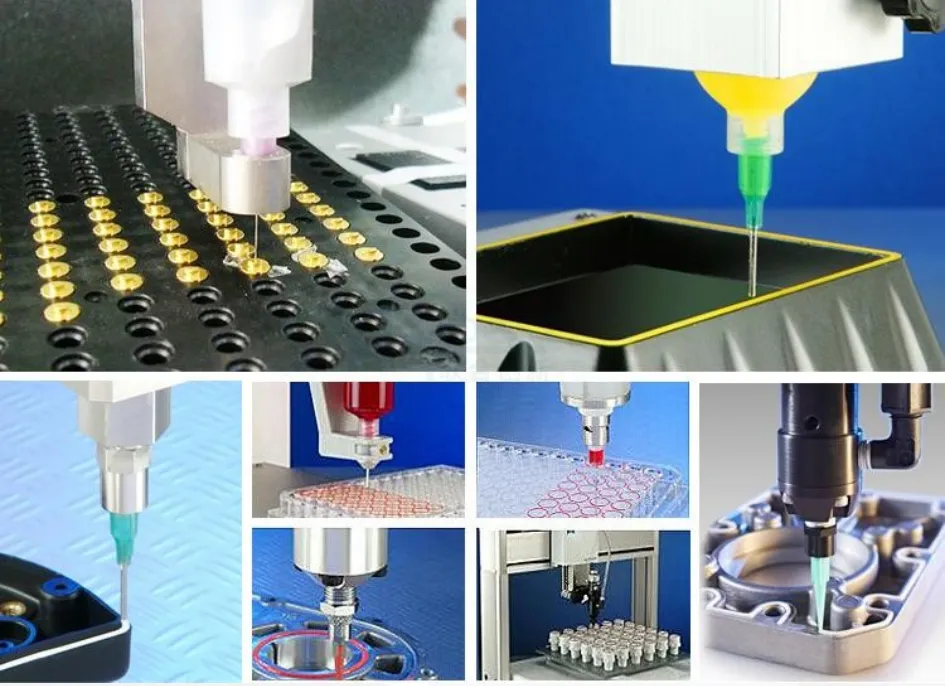

Using an automatic glue dispensing machine involves a series of steps to ensure accurate and efficient application of adhesive. Below is a general guide on how to use such a machine:

1. Preparation:

Select the Right Adhesive: Choose the appropriate adhesive or glue that suits your application requirements. Ensure that the viscosity of the glue matches the specifications recommended by the machine manufacturer.

Prepare the Work Area: Clean the work surface to prevent contamination. Ensure the area is well-ventilated, and safety precautions, such as wearing protective gear, are taken if necessary.

2. Set Up the Machine:

Power On: Turn on the automatic glue dispensing machine and allow it to reach the required operating temperature, especially if the adhesive requires heating.

Calibration: Calibrate the machine according to the type of adhesive being used. Adjust settings such as dispensing speed, volume, and pattern based on your specific application needs.

3. Load the Adhesive:

Fill the Reservoir: Pour the adhesive into the machine's reservoir or cartridge. Ensure that the reservoir is clean and free from any contaminants.

Check for Air Bubbles: Purge the system of any air bubbles that may affect the dispensing accuracy. Follow the manufacturer's guidelines for proper priming or purging procedures.

4. Adjust Dispensing Parameters:

Set Dispensing Parameters: Depending on your application, adjust parameters such as dispensing pressure, speed, and pattern. The automated glue dispenser may have a user interface or control panel where you can input these settings.

5. Test Dispensing:

Featured content:Guide to Buying a crawler scissor liftThe Benefits of Using Rough terrain scissor lift5 Advantages of Using Barrel Plating Equipment: Enhancing Your Metal Finishing ProcessesBackground History of CrusherHow can I find the best Heavy Metal Shredder Solution for my business?4 Advice to Choose a 3150kw Scrap Shredder10 Things to Consider When Buying types of scrap shredderPerform Test Runs: Before applying the adhesive to your actual workpiece, run a series of test dispenses on a scrap material. This allows you to fine-tune the settings and ensure the machine is dispensing the right amount of glue accurately.

6. Position Workpiece:

Secure Workpiece: Position the workpiece securely on the work surface. Ensure it is in the correct location for precise adhesive application.

7. Start Dispensing:

Initiate Dispensing: Once satisfied with the test runs, start the automatic glue dispensing machine. The machine will apply the adhesive according to the programmed parameters onto the designated areas of the workpiece.

8. Monitor and Adjust:

Monitor the Process: Keep an eye on the dispensing process to ensure that it is proceeding smoothly. Address any issues promptly, such as inconsistent dispensing or clogging.

Adjust as Needed: If adjustments are required during the dispensing process, use the machine controls to modify parameters like dispensing volume, speed, or pattern.

9. Post-Dispensing Clean-Up:

Shut Down Properly: Once the dispensing is complete, follow the manufacturer's guidelines for shutting down the machine. This may involve purging the system, cleaning dispensing nozzles, and turning off the machine.

Using an automatic glue dispensing robot efficiently requires a good understanding of the specific machine's features and the characteristics of the adhesive being used. Regular maintenance and adherence to the manufacturer's instructions are essential to ensure consistent and reliable performance over time.

Featured content:Ozone Generator Market Size, StrategiesEverything You Need To Know To Find The Best Smt Automatic Turning ConveyorHow does a pizza dough rounder work?The Benefits of Using a Cardboard Baler for Recycling and ...Nickel electroplatingIndustrial Air Compressors6 Essential Safety Gears and Tools for Laser Cutting

Comments

Please Join Us to post.

0