G-Top contains other products and information you need, so please check it out.

G-Top Product Page

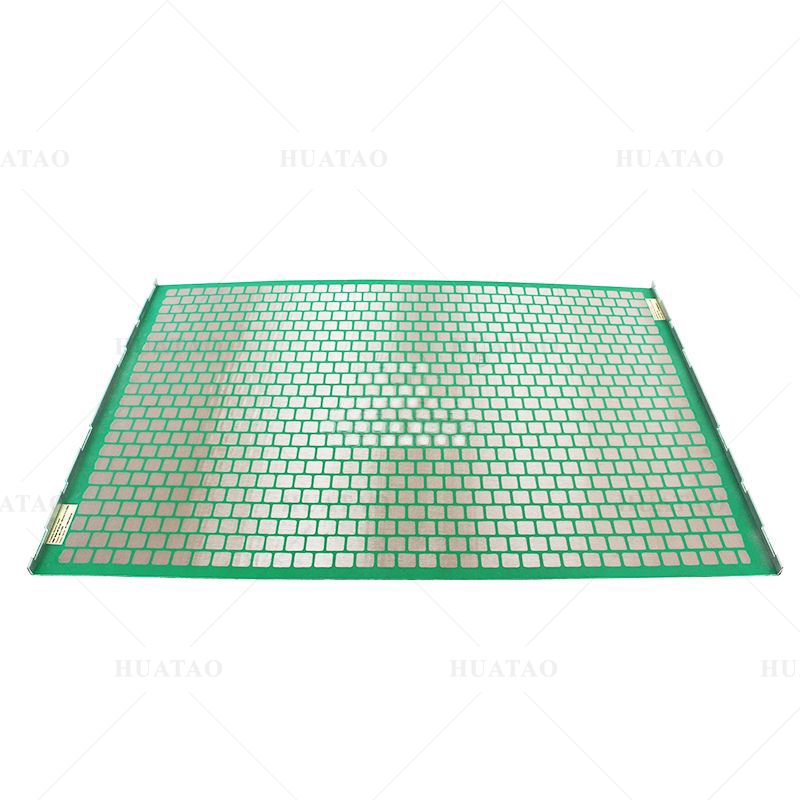

Ground engaging equipment maintenance is crucial for efficiency and safety

Step 1: Regular inspections

Regular inspections of ground engaging equipment such as buckets, blades, teeth, and cutting edges are crucial to ensure they are in good condition. Inspections help to identify any signs of wear and tear, cracks, or damage that need to be addressed. This preventive measure helps to avoid equipment failure during operation, which can lead to costly downtime and repairs.

Step 2: Cleaning and lubrication

After each use, it is important to clean ground engaging equipment thoroughly to remove dirt, debris, and build-up that can cause wear and corrosion. Lubricating moving parts helps to reduce friction and extend the lifespan of the equipment. Neglecting to clean and lubricate can result in premature wear and damage, affecting the performance and efficiency of the equipment.

Step 3: Repair and replacement

If any signs of wear or damage are detected during inspections, it is crucial to address them promptly. Repairing or replacing worn-out parts helps to maintain the integrity and effectiveness of the equipment. Ignoring these issues can lead to safety hazards for operators and other workers on the job site.

Step 4: Proper storage

Proper storage of ground engaging equipment when not in use is essential to protect it from environmental factors such as moisture, sunlight, and extreme temperatures. Storing equipment in a dry and secure location helps to prevent rust, corrosion, and other forms of damage. This prolongs the lifespan of the equipment and ensures it is ready for use when needed.

Step 5: Training and education

Providing training and education to operators on the proper use and maintenance of ground engaging equipment is crucial for safety and efficiency. Operators should be aware of best practices for operating the equipment, as well as how to identify and address maintenance issues. Investing in training helps to prevent accidents and breakdowns that can result from improper use or neglect.

In conclusion

Maintaining ground engaging equipment is essential for ensuring efficiency, safety, and longevity. By following these steps and implementing a proactive maintenance plan, operators can prevent costly downtime, repairs, and accidents. Regular inspections, cleaning, repair, storage, and training are all key aspects of proper maintenance that contribute to the overall success of equipment operations.

Check now

Featured content:5 Must-Know Tips for Choosing the Best Tapered Button BitWhat are the benefits of investing in new digger bucket teeth for a B2B company?Forging vs. Casting: 6 Key Differences to ConsiderDTH HammersWhat Are the Advantages of bucket adapters supplier?ROK - Foam roll compression machine | BäumerKey Questions to Ask When Ordering Hebei Yogem

Please visit our website for more information on this topic.

Featured content:Which stainless steel pump casting is best?Mud PumpsBelleville101: What are Belleville Washers and Disc Springs?5 Reasons Why Your Business Needs elevator links drilling company?How to Save Money When Buying ductile iron sand casting supplierKey Questions to Ask When Ordering wellhead api 10d ball screw gate valveDiscover the Top Products and Services of Hubei Yiyuan Industrial Trading Co., Ltd

Comments

Please Join Us to post.

0