Welcome to a comprehensive exploration of the benefits of using a pet food extruder. As passionate pet owners and advocates for optimal pet nutrition, we're here to delve into the world of pet food production and shed light on the advantages of utilizing a pet food extruder. These advanced machines have revolutionized the way pet food is prepared, ensuring that our beloved companions receive the nutrition they deserve. In this article, we'll uncover the reasons why Pet Food Machine have become an essential tool for both pet food manufacturers and pet parents.

Pet food extruders are specialized machines designed to process and shape pet food ingredients into the desired final product. The extrusion process involves subjecting a mixture of ingredients to high temperature and pressure, resulting in a transformation of texture and structure. This process not only enhances palatability but also improves the nutritional value and digestibility of the pet food.

Advantages of Using a Pet Food Extruder

1. Enhanced Nutrient Retention

One of the standout benefits of utilizing a pet food extruder is its ability to retain a higher proportion of nutrients during processing. The controlled high-temperature environment helps break down anti-nutritional factors, making essential nutrients more bioavailable to pets. This translates to improved digestion and better absorption of nutrients.

2. Improved Digestibility

The extrusion process involves the expansion and gelatinization of starches, which enhances digestibility. The transformation of ingredients into a more digestible form ensures that pets can extract maximum nutrition from their food, reducing the likelihood of gastrointestinal issues.

3. Uniform Texture and Shape

Pet food extruders allow manufacturers to create uniform textures and shapes, which not only appeal to pets visually but also contribute to a consistent eating experience. This is especially beneficial for pets with dental issues or those requiring specific dietary needs.

4. Customizable Formulations

Pet food extruders offer flexibility in formulating recipes to cater to various pet preferences and nutritional requirements. Manufacturers can easily adjust ingredient ratios and formulations to meet specific dietary needs, ensuring that pets receive tailored nutrition.

5. Food Safety and Quality

The extrusion process involves high temperatures that effectively kill harmful microorganisms, ensuring the safety of the final product. Additionally, the hermetic environment of the extruder minimizes exposure to contaminants, contributing to the overall quality and safety of the pet food.

6. Longer Shelf Life

The extrusion process not only enhances nutrient retention but also extends the shelf life of pet food. The reduction of moisture content and the elimination of potential contaminants help prevent spoilage, ensuring that the food remains fresh and nutritionally viable for a longer duration.

7. Sustainability

Pet food extruders can be part of sustainable manufacturing practices. By efficiently processing ingredients and reducing waste, these machines contribute to more responsible production methods, aligning with the growing demand for environmentally friendly practices.

8. Time and Cost Efficiency

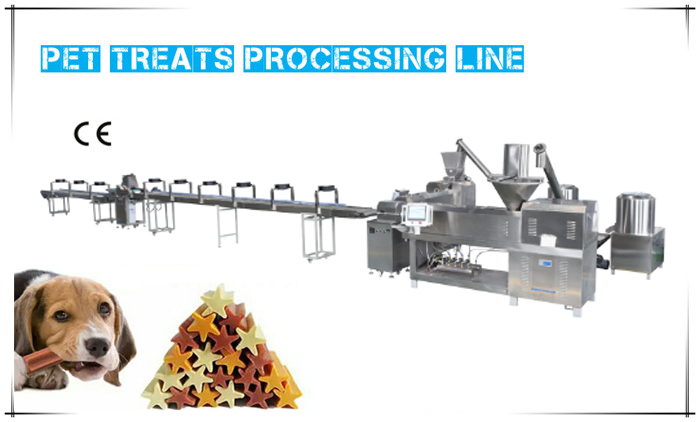

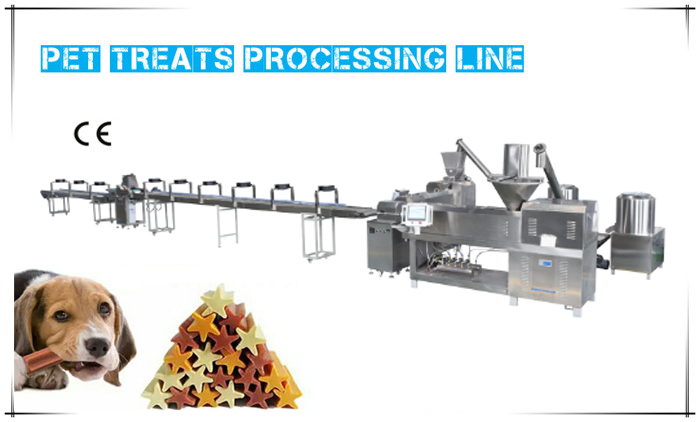

The streamlined process of Pet Treats Extrusion Line leads to time and cost savings for manufacturers. With quicker processing times and reduced labor requirements, manufacturers can produce larger quantities of pet food in a more efficient manner.

Conclusion

In conclusion, the benefits of using a pet food extruder are far-reaching and impactful, revolutionizing the way pet food is prepared and enhancing the quality of nutrition provided to our furry companions. From improved nutrient retention and digestibility to customizable formulations and enhanced food safety, pet food extruders have become a cornerstone of modern pet food production. Whether you're a pet food manufacturer seeking innovation or a dedicated pet parent aiming to provide the best for your pet, considering the advantages of pet food extruders is a step toward elevating pet nutrition to new heights.

Comments

Please Join Us to post.

0