Safety valve grinders are indispensable tools in industries where safety and precision are paramount. These specialized devices play a vital role in maintaining and ensuring the proper functioning of safety valves, which are critical components in various industrial processes. In this article, we will explore the significance of safety valve grinders, their operation, benefits, and key considerations.

The Importance of Safety Valve Grinders

Safety valves are designed to release excess pressure from systems to prevent overpressure, potential explosions, or equipment damage. Properly functioning safety valves are crucial for the safety of personnel, equipment, and the environment. Safety valve grinders play a vital role in maintaining the effectiveness of these valves by ensuring their proper seating and sealing.

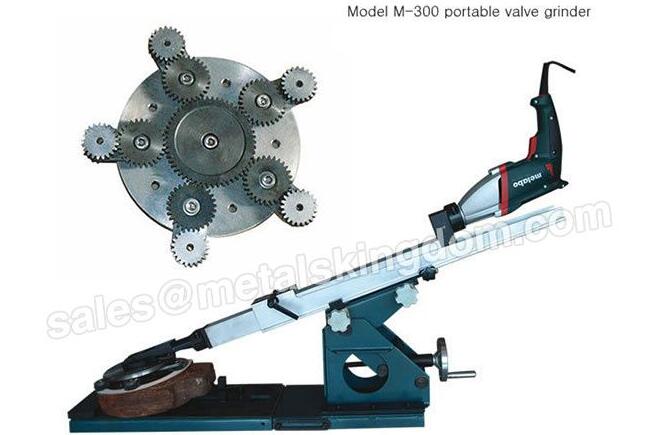

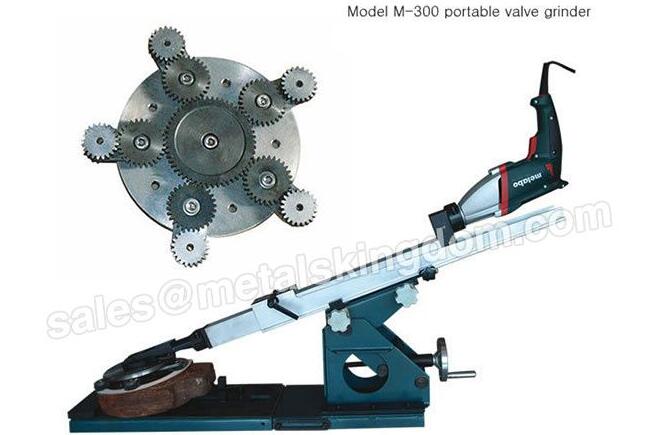

How Safety Valve Grinders Work

Valve Removal and Inspection

The safety valve is carefully removed from the system and inspected for wear, damage, and irregularities. Any buildup of deposits or residue is also examined.

Preparation of the Valve Seat

The valve seat is prepared by cleaning it thoroughly and, if necessary, applying an appropriate grinding compound. This compound aids in creating a precise and smooth surface for the valve to seat against.

Grinding Process

The safety valve grinder is then employed to grind and smooth the valve seat surface. This process helps ensure proper contact and sealing between the valve and its seat.

Checking Valve Sealing

After grinding, the valve is reinstalled, and a pressure test is conducted to confirm that the valve is sealing effectively.

Benefits of Using Safety Valve Grinders

Enhanced Safety

The primary benefit of safety valve grinders is the improvement in safety. Properly ground and seated safety valves ensure reliable pressure relief when needed, preventing potential accidents.

Extended Valve Lifespan

Regular maintenance using safety valve grinders can extend the lifespan of safety valves by preventing wear and damage that can result from improper seating.

Optimized Performance

Safety valve grinders ensure that safety valves function as intended, maintaining system integrity and preventing disruptions in industrial processes.

Cost Savings

By preventing valve failures and system breakdowns, safety valve grinders contribute to cost savings associated with repairs, downtime, and potential legal liabilities.

Key Considerations when Using Safety Valve Grinders

Expertise and Training

Operating safety valve grinders requires proper training and expertise. Personnel should be well-versed in the equipment's operation and safety protocols.

Regular Maintenance

Safety valve grinders themselves should be regularly inspected and maintained to ensure their accuracy and reliability.

Valve Types and Applications

Different industries use various types of safety valves. It's essential to understand the specific requirements of the valves in use.

Conclusion

Safety valve grinding machines are indispensable tools that contribute significantly to industrial safety, performance, and efficiency. By ensuring the proper seating and sealing of safety valves, these devices prevent overpressure incidents and potential hazards, promoting the well-being of personnel and the environment. The benefits of extended valve lifespan, optimized performance, and cost savings make safety valve grinders an essential investment in industries where safety and precision are paramount.

Comments

Please Join Us to post.

0