CNC lathe machines have revolutionized the field of machining and manufacturing. These sophisticated machines combine computer programming and automation to perform precise and intricate turning operations. If you're new to CNC lathe machines or interested in understanding their capabilities, this comprehensive guide will provide you with a solid introduction to their workings, applications, and advantages.

What is a CNC Lathe Machine?

A CNC lathe machine is a computer-controlled machine tool used for shaping and machining cylindrical workpieces. It operates by rotating the workpiece while a cutting tool moves along its length, removing material to create the desired shape. The movements and actions of the machine are controlled by pre-programmed instructions, enabling highly precise and repeatable operations.

Components of a CNC Lathe Machine

A typical CNC machine consists of several essential components. These include the bed, headstock, spindle, chuck, tool turret, tailstock, and control panel. Each component plays a crucial role in the machine's overall functionality and contributes to its precision and versatility.

How CNC Lathe Machines Work

CNC lathe machines operate based on programmed instructions called G-code. These instructions specify the tool's movement, feed rate, depth of cut, and other parameters. The machine's computer controller interprets the G-code and coordinates the movements of the spindle, tool turret, and other machine components to perform the desired machining operations.

Applications of CNC Lathe Machines

CNC lathe machines find applications in a wide range of industries, including automotive, aerospace, electronics, medical, and more. They are used to create intricate and precise components such as shafts, cylinders, threads, grooves, and complex geometries. CNC lathe machines are valued for their ability to produce high-quality parts with tight tolerances and consistency.

Advantages of CNC Lathe Machines

CNC lathe machines offer several advantages over conventional lathes. These include:

a. Precision and Accuracy: CNC lathe machines provide exceptional precision and accuracy, ensuring consistent results even with complex operations and tight tolerances.

b. Efficiency and Productivity: The automation and computer-controlled operations of CNC lathes result in improved efficiency and higher productivity. These machines can run unattended for extended periods, minimizing manual intervention.

c. Flexibility and Versatility: CNC lathe machines are highly versatile and can perform a wide range of machining operations. With the ability to switch between tools and adapt to various workpieces, they offer flexibility in manufacturing processes.

d. Time and Cost Savings: CNC lathe machines reduce the time and cost associated with manual labor, setup, and changeovers. They enable faster machining speeds and eliminate human errors, resulting in optimized production processes.

e. Complex Machining Capabilities: CNC lathe machines excel in handling complex machining tasks, including multi-axis operations, thread cutting, grooving, and contouring. This versatility expands the range of components that can be produced.

Training and Skills

Operating a CNC lathe machine requires specialized training and knowledge. Operators need to understand programming languages, tooling, machine setup, and maintenance procedures. Training programs and resources are available to develop the necessary skills for effective operation.

In conclusion, CNC lathe machines have transformed the manufacturing industry with their precision, automation, and versatility. By understanding the fundamentals of these machines, their components, working principles, applications, and advantages, you can appreciate their role in modern machining processes and explore their potential for various manufacturing needs.

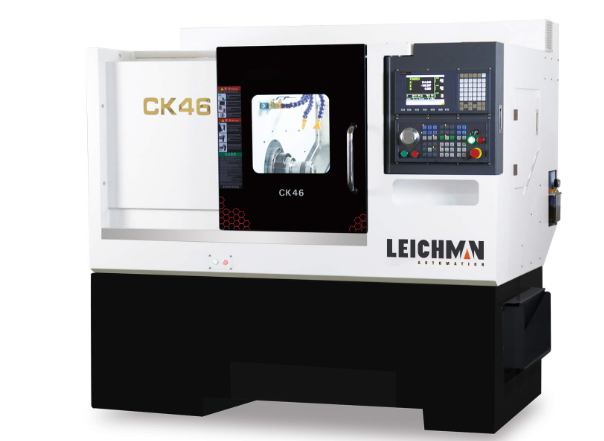

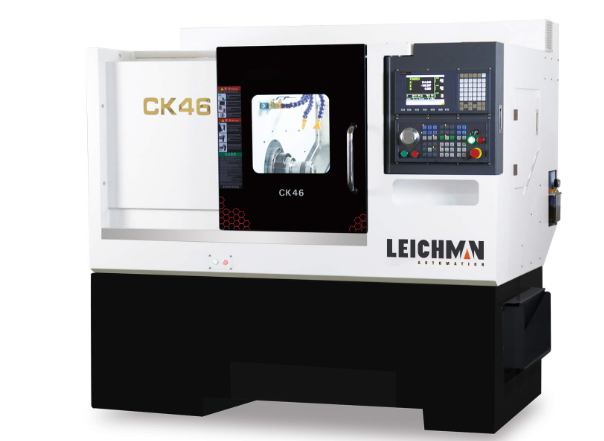

Leichman is a high-tech enterprise specializing in the R&D, design, production and sales of CNC machine tools. It is committed to the standard leadership, core manufacturing and technological breakthroughs of high-end precision CNC lathes and CNC metal spinning machines. "head to the World".

Comments

Please Join Us to post.

0