With the development of society and the progress of science and technology, heat treatment technology is also making continuous progress. Vacuum atmosphere heat treatment furnace manufacturer HAOYUE in our many years of practice based on a simple sharing for you.

Multifunctional A5-17 Atmosphere Sintering Furnace

Oxygen-free/vacuum

Oxygen-free heat treatment, from the protective atmosphere heating instead of oxidation atmosphere heating, and then to the nitrogen potential of controlled atmosphere heating, heat treatment after the performance of the parts are improved, heat treatment defects such as oxidation, decarburization and cracking are greatly reduced. The amount of finish machining left after heat treatment is reduced, which improves the utilization of materials and machining efficiency.

True air quenching, vacuum or low-pressure carburizing, nitriding, nitrogen-carbon penetration and boron penetration, etc. can significantly improve the quality of the workpiece, reduce distortion and improve life.

Energy saving

Energy-saving heat treatment using new insulation materials to improve the energy utilization rate of heat treatment equipment; optimize the heat treatment process, improve the process yield and give full play to the capabilities of the equipment. At this stage, manufacturers are doing experiments in this area, such as making full use of waste heat, waste heat, some manufacturers have used forging waste heat for spheroidal annealing of bearing parts; the use of low energy consumption, short-cycle process instead of long-cycle, energy-consuming process, etc.

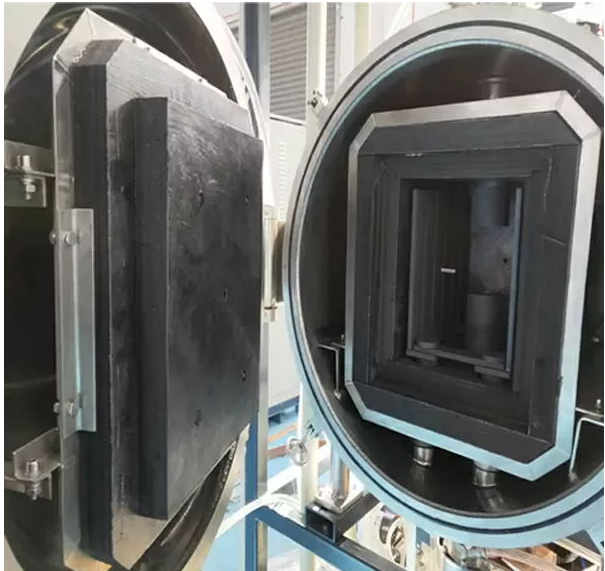

Hot Sale P4 Vacuum Hot-Pressing Sintering Furnace

Precision treatment

Precision heat treatment is to fully ensure the stability of the optimization process, to achieve a small dispersion of product quality (or zero), heat treatment distortion to zero, reduce the amount of grinding left to improve productivity and save materials. To achieve precision heat treatment must have good furnace temperature uniformity, temperature control accuracy, and good cooling and stability of the quenching agent.

Pollution treatment

Heat treatment production formed by waste water, waste gas, waste salt, waste oil and electromagnetic radiation will cause environmental pollution. To solve the problem of environmental pollution of heat treatment, the implementation of clean heat treatment is one of the directions of heat treatment technology development. This puts high demands on the heat treatment atmosphere, quenching oil and cleaning equipment.

Preparation of Diamond / Aluminum Composite

Sintering Furnace

There are many types of sintering furnaces, which can be roughly divided into vacuum sintering furnace, tunnel type enamel sintering furnace, alumina sintering furnace, drill sintering furnace, etc.

Vacuum sintering furnace is mainly used for sintering of high chromium cast steel rolls, sintering of welded stress after welding of roll surface and sintering for other purposes, microcomputer high-precision execution of sintering process curve, installation of designed hot air internal circulation guide system, very high temperature uniformity.

Tunnel type enamel sintering electric furnace energy-saving continuous operation sintering electric furnace, mainly for the enamel industry sintering, enamel decorative panels, bathtubs, gas stove panels and other large enamel products.

Alumina sintering furnace is mainly used for alumina sintering, sintering process using microcomputer program process curve fully automated precision temperature control, supporting powder sintering charging sagger.

Cart type drill sintering furnace is mainly used for mining and petroleum alloy drill sintering, fully automatic execution of the sintering process curve, is a widely used heat treatment equipment in the alloy sintering industry.

When choosing a vacuum heat treatment furnace, you should first understand the parameters of the furnace, but also pay attention to the product after-sales service issues. Shanghai Haoyue Technology Co., Ltd. is a manufacturer with more than 20 years of production, design and manufacture of vacuum heat treatment equipment and sintering furnace, with a wealth of experience, if you need, please contact us promptly.

Comments

Please Join Us to post.

0