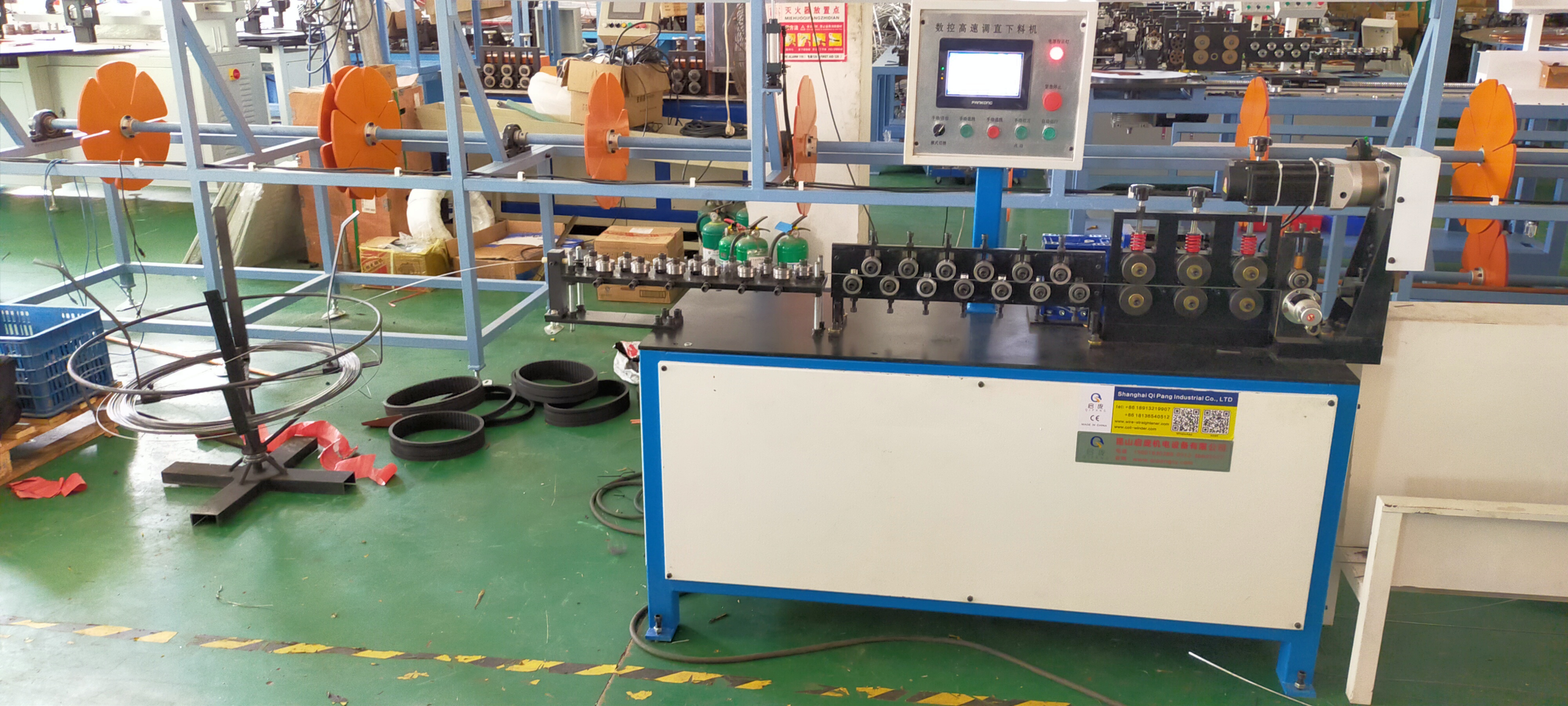

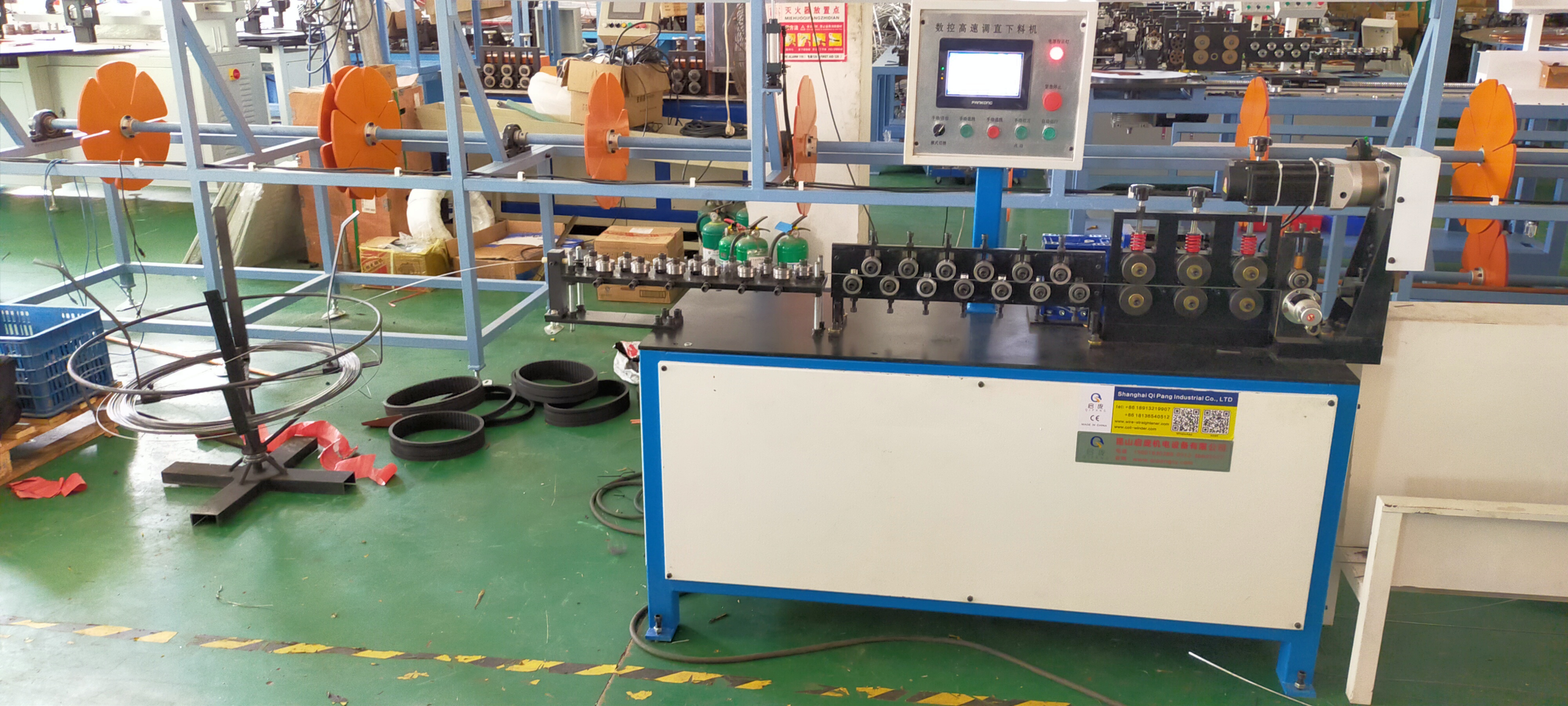

Steel mills are at the heart of many industrial processes, responsible for transforming raw materials into essential products for a wide range of industries. In this intricate web of production, the efficiency of steel mills can significantly impact the cost and availability of various products. One key technology that has revolutionized the steel manufacturing process is the Flying Shear Quick Straightening and Cutter. This article delves into the vital role these machines play in steel mills and how they have transformed the industry.

Understanding Flying Shear Quick Straightening and Cutter

The Flying Shear Quick Straightening and Cutter is a multifunctional machine that combines two critical processes: shearing and straightening. Let's break down its essential functions:

Shearing: In the context of steel mills, shearing refers to the process of cutting steel coils or bars into specific lengths. This is a crucial step as it determines the size of the end product.

Straightening: Steel often arrives at mills with imperfections, bends, or curvatures. Quick straightening is the process of correcting these deformities, ensuring the steel is perfectly straight and uniform, which is essential for high-quality end products.

The Advantages of Flying Shear Quick Straightening and Cutter

Now, let's explore how these machines benefit steel mills:

Efficiency: The Flying Shear Quick Straightening and Cutter can operate continuously without halting the production line, significantly reducing downtime and increasing overall efficiency.

Precision: These machines offer a high level of precision, ensuring that the cut and straightening processes are accurate and consistent. This precision is vital for meeting tight tolerances in various steel products.

Cost Savings: By optimizing the use of raw materials and reducing waste, these machines contribute to cost savings in the steel production process.

Increased Output: The speed at which the Flying Shear Quick Straightening and Cutter operates means that steel mills can achieve higher output rates, leading to increased productivity.

Quality Improvement: The straightening process enhances the quality of the steel by eliminating deformities, ensuring the final product meets the required standards.

Applications in Steel Mills

Flying Shear Quick Straightening and Cutter machines are used in a variety of steel mill processes, including:

Bar Production: In the production of steel bars, these machines are instrumental in cutting and straightening the bars to the desired length and shape.

Coil Processing: Steel coils arrive at mills with variations in thickness and curvature. Flying Shears help in cutting coils into sheets and straightening them before further processing.

Wire Rod Production: For manufacturing wire rods used in various applications, these machines play a pivotal role in achieving the correct dimensions and quality.

The Flying Shear Quick Straightening and Cutter have become an indispensable part of modern steel mills. Their ability to combine shearing and straightening processes with efficiency, precision, and cost-effectiveness has revolutionized the steel production industry. They ensure that the end products meet stringent quality standards while optimizing the use of raw materials and increasing overall productivity. As steel continues to be a cornerstone of industrial progress, these machines are set to play an increasingly vital role in shaping our world.

Comments

Please Join Us to post.

0