Top Eco Friendly Packaging Materials in

Recyclable Plastic

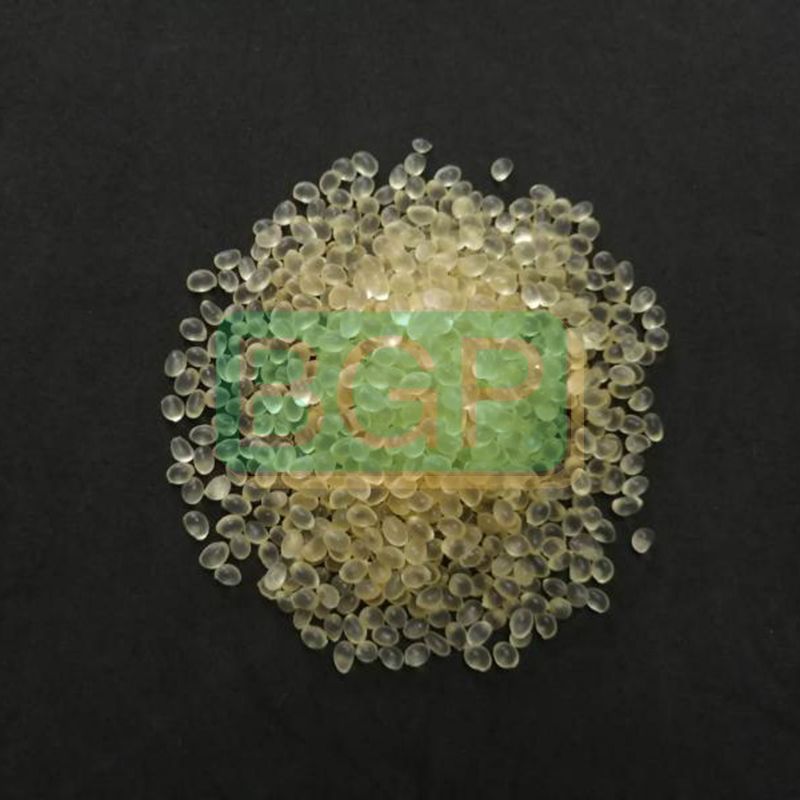

Recyclable plastic has been around for a while, and for good reason. Recyclable plastic packaging is durable and lightweight; however, it does come with a high carbon footprint compared to others on our list.

If you want to learn more, please visit our website custom compostable bags.

Some of the most commonly recycled plastics are:

-Polyethylene Terephthalate (PET):

This type of thermoplastic polymer resin is used to create fibers for clothing, food and liquid containers, and thermoforming for manufacturing. This is because PET is an inert material that is recognized by health authorities as a safe plastic. Like glass, PET is hygienic and generally resistant to bacteria and other microorganisms.

You'll find PET in your plastic food containers, plastic water bottles, and in clothes and textiles made of recycled plastic.

-Recycled Polyethylene Terephthalate (rPET):

rPET is made from recycled and reprocessed PET plastic to make something new. The best thing about rPET is that it's 100% recyclable, meaning that it can be reintroduced into the loop many times, decreasing the need for resource extraction and drastically reducing carbon footprint. The process of sorting, washing, and flaking reused PET to make new rPET requires much less energy (75% less) than creating virgin plastic.

Not only is rPET used to make new plastic bottles, but it can also be found in many different products such as activewear, outdoor gear, bedding, pet beds, and even stuffing for toys. Anything made of polyester can include recycled PET.

'Polypropylene (PP):

Another type of safe thermoplastics is PP Plastic. This type of recyclable plastic is approved by the FDA to be used in food containers, so you'll find it in many applications, including packaging for food products, detergents, and other consumer goods. PP is also used to create automotive plastic parts and textiles.

Compostable Packaging

Compostable packages, also known as bioplastics, are made from natural materials, such as sugar cane and corn starch, that break down and return to the earth without leaving behind traces of toxic chemicals'making it a sustainable option for businesses that reduces waste and saves money. Compostable packaging materials are available in paper, cardboard, and plant based plastics.

However, not all compostable packages can be added to your compost pile at home. Some products are suitable for home composting, while others need commercial composting.

Home Composting VS Commercial composting.

Home composting is a great option for disposing materials without harming the environment. However, not all organic material can be completely decomposed at home. Some compostable foodservice packages need commercial composting. Materials accepted at commercial sites typically require higher composting temperatures than what's safe to add to home compost piles. Moreover, if the compost comes from a commercial composting site, it can be resold and used as fertilizer.

The most popular two types of compostable packaging are PLA and CPLA

-Polylactic acid (PLA):

Polylactic acid is a type of polyester made from plant starch from corn, sugarcane, maize, cassava, or sugar beet pulp. All of these renewable sources have one thing in common'sugar. The sugar from these plant-based sources is fermented and turned into lactic acid, which is later made into polylactic acid.

One of the main environmental advantages of PLA over plastic is its life cycle. Starting from the manufacturing process, the carbon emissions associated with PLA production are 80% lower than that of other plastics. PLA is also biodegradable, which means it can decompose into the earth without leaving behind any harmful chemicals.

However, since it's biodegradable, PLA can deform when exposed to heat, which means it can't be left in the sun, or used in a microwave, or exposed to any source of heat.

Along with being one of the most popular materials used in desktop 3D printing, PLA is also used in compost bags, food packaging, disposable tableware, and loose fill packaging. As a fiber, PLA is used for disposable clothing, upholstery, diapers, and feminine hygiene products.

-Crystallized Polylactic Acid (cPLA):

cPLA is processed by applying high pressure and heat to PLA, chalk, and other biodegradable additives. This causes the material to crystallize, creating a harder product that's less susceptible to heat degradation than regular PLA.

cPLA is commonly found in the lids of the disposable coffee cups you grab every morning before heading to work.

Corrugated Packaging

Corrugated packaging is made from corrugated paperboard. It is a strong, lightweight, and durable material that's widely used in the packaging industry. Corrugated packaging is 100% recyclable. It is also biodegradable and compostable, making it an excellent choice for eco friendly sustainable packaging.

Corrugated packaging, such as cardboard, has a high resistance to crushing and tearing, making it ideal option for shipping boxes to protects all types of products during transport.

Almost all items which are shipped to a business or customers, use this most commonly used format of eco friendly packaging.

Kraft Paper

Like all paper, kraft paper is made from wood pulp, which is a renewable natural resource. Its sustainability comes from its eco friendly production process.

Krafts paper widely used in packaging because its high tear-resistance, its light weight, and its nature-themed aesthetic.

High tear-resistance:

Kraft paper is by far the strongest paper material used in packaging. Kraft paper is treated with minimum chemicals to help reserve its durability and strength. That way, it results in higher tensile strength, and it is less likely to tear or fray. Thanks to its strength and durability, Kraft paper can be reused several times before recycling it.

Lightweight:

Kraft paper is not only famous for high tear-resistance, but it's also lightweight and doesn't take up much space, which makes it beneficial to keep the shipping costs down.

Nature-themed product packaging:

One of the unique characteristics of kraft paper is its natural-colored coarse texture. It makes kraft paper the perfect representative of the nature-themed product packaging for any businesses selling natural and organic products.

With increasing demands for different colors, kraft paper is bleached to get other shades of its natural brown color. The bleaching extent is adjusted to bring out the natural brown kraft paper, creamy kraft paper, and black kraft paper. Light colors indicate that more bleaching is involved and thus the surface will turn out smoother.

Generally, it is best to print a single color on kraft paper to emphasize the natural texture of this special paper material. However, the kraft paper color will differ from batch to batch due to the different material sources and different times of harvesting during different weathers.

Kraft papers usually come in the form of paper sheets to fill a carboard box and secure its contents, or as paper bags that come in all shapes and sizes depending on their intended use.

Reusable Packaging

Tin

As a primary raw material in the packaging industry, tin is 100% recyclable and sustainable. it is malleable and could be process and returned to the production cycle without losing its quality. When processed, tin could be welded into corrosion-resistant tin cans and containers.

Steel

Stainless Steel are eco friendly containers because they producer less carbon emissions when they're produced, and they have a long-life span since they could be reused multiple times. When it's time to be replaced, stainless steel could be recycled to start a new lifecycle.

Additionally, Stainless steel food containers and bottles are toxin free and they're save to use with hot foods and beverages, which gives them an edge over other types of eco friendly materials.

Aluminium

Aluminium is the most cost-effective material to recycle, since it uses only 5% of the energy needed to make it from raw materials. In addition, all the leftover scraps from the production process could be melted down and become reusable again and again. This is why aluminium is one of the best alternatives in the market for any single-use packaging solution.

Featured content:How to Choose the Best Sharp Titanium Cga-668?Top Benefits of Bulk Drill Bits: Save Money & Time!Turf Latex: Enhancing the Durability and Aesthetics of Artificial Grass InstallationsHydroxypropyl Methylcellulose (HPMC): A Multifunctional Marvel in IndustriesUnlocking the Potential of Methyl Hydroxyethyl Cellulose (MHEC) in Various ApplicationsDEVELOPMENT TREND OF SURFACTANT APPLICATIONWhat does ammonium sulphate do to plants?

For more information, please visit is cornstarch biodegradable.

Aluminium trays are perfect solution for storing and preserving all types of foods because aluminium provides a 100% water and gas resistance. Moreover, it's corrosion resistant to substances in the pH range from 4 to 9.

Glass

Glass is made of 4 main ingredients: sand, soda ash, and limestone. Nonetheless, glass packages are 100% recyclable and can be endlessly recycled with no loss of quality. Glass jars, bottles, and other types of glass containers can all be reused or repurposed in a variety of ways

Consumers always have brilliant ideas to reuse glass containers, such as DIY crafts and projects, storage containers, a vase, a drinking glass, or a bottle to store your freshly squeezed orange juice.

Whichever way you reuse your glass containers, make sure you sanitize the glass between each use.

Bubble Wrap

Bubble wrap has always been an essential material for protecting fragile products while moving or delivering them. When their purpose is done, they could be stored and reused again! If the sheet is still in perfect condition, it could be used once more to move your fragile objects. But if it has takes a few hits, there are plenty of other ideas to reuse it. It could still be used to insulate your home or your plants, or line your grocery bag to protect any breakable or squishable goods. If all else fails, it's a great way to relief your stress or entertain your children.

Glassine packaging

Glassine is a paper-like recyclable and compostable material made from wood pulp. It is FDA approved to come in contact with food, making it the best packaging choice for baked goods and confections. Glassine is also grease and moisture resistant, but not waterproof. That way it'll keep your baked goods fresh and prevent moisture caused by condensation.

Mushroom packaging

Mushroom Packaging is a 100% biodegradable and compostable packaging solution. Mushrooms can be grown in weeks with food wastes, which makes them a renewable source.

Mushroom packages are extremely strong and versatile. Manufacturers are now using it to create everything from containers, to insulation, to packing peanuts.

Green Cell Foam

Green Cell Foam is a natural material. It's made of non-GMO cornstarch, which leaves it with a 12-month lifecycle. Green cell foam is biodegradable, comostable, water-soluble, and dissolves in 1 minute when subjected to heat. All of which make it easy to decompose in moist soil in your backyard.

Green Cell Foam is used to package a wide variety of products, including electronics, aircraft parts, perishable foods, temperature-sensitive pharmaceuticals, and so much more.

Cellulose packaging

Cellulose is a natural renewable resource derived from wood or plants. Because its natural, cellulose makes a great biodegradable and compostable material. As an F&B business, cellulose is the key to help your business go green. Cellulose packaging is strong, durable, and it can be printed to create custom packaging for your business.

One of the famous uses of cellulose packaging is cellulose coffee pods and cellophane. Cellophane is an oil and moisture resistance, clear, thin plastic-like material that is used to store and display food items. You'll usually find nuts, baked goods, and other greasy foods wrapped in cellophane to help preserve them.

Seaweed packaging

Seaweed is a natural renewable resource than can be grown in fresh or salt water and requires no additional media for growth. The nutrients and fibers in seaweed not only make it a great eco friendly packaging material, but it's also used to explore innovative edible packaging options.

Seaweed packaging material is made from dried and shredded seaweed. It is biodegradable, recyclable, and can be reused for several times before needing replacement. Moreover, seaweed packaging material is also compostable and can be used as a soil amendment or mulch.

Seaweed is non-toxic, odorless, and does not leach chemicals into the food that's wrapped in it. It is flexible, yet strong, making it ideal for wrapping delicate goods.

As a paper bag manufacturer, we're often asked whether our paper bags are recycled, recyclable, biodegradable, or compostable. And the simple answer is that, yes, WCI manufactures paper bags that fall into those various categories. We'd like to provide more information on some common questions regarding paper bags and their environmental implications.

What's the difference between biodegradable paper bags and compostable paper bags?

In a world where many 'eco-friendly' terms are thrown around interchangeably to attract buyers, even the most well-intentioned consumer can feel misinformed. Some common terms you may hear when making decisions regarding which environmentally responsible packaging best suits your product or brand are:

Biodegradable Bag: A bag that will break down into carbon dioxide, water, and biomass within a reasonable amount of time in a natural environment. Note that just because something is marked as biodegradable, it requires certain conditions to do so. Landfills lack microorganisms and organisms required for waste to degrade. And if it's disposed of inside another container or plastic bag, biodegradation may not occur in a timely fashion.

Compostable Bag: The EPA definition of compostable is an organic material that will decompose under a controlled biological process in the presence of air to form a humus-like material. Compostable products must biodegrade within a reasonable amount of time (a couple months) and produce no visible or toxic residues. Composting may occur in an industrial or municipal composting site or in a home composter.

Recyclable Bag: A bag that can be collected and reprocessed to produce new paper. Paper recycling involves mixing the used paper materials with water and chemicals to break them down into cellulose (an organic plant material). The pulp mixture is strained through screens to remove any adhesives or other contaminants and then de-inked or bleached so it can be made into new recycled paper. Check out this simple illustration from Earth Answers.

Recycled Paper Bag: A paper bag made from paper that has been used before and put through the recycling process. The percentage of post-consumer fibers means how much of the pulp used to make the paper has been used by a consumer. Examples of post-consumer materials are old magazines, mail, cardboard boxes, and newspapers. For most bag legislation, a minimum of 40% post-consumer recycled content is required to be compliant. Many paper bags manufactured in our facility are made with 100% post-consumer recycled material.

Is it better to recycle a paper bag, or to compost it?

Either option is acceptable but please, DON'T THROW IT IN THE TRASH! Unless they have been heavily contaminated with grease or oils from food, or are laminated with poly or foil, paper bags can be recycled to make new paper products or composted.

Recycling can have a larger-scale environmental impact than composting because there is generally greater access to recycling programs than to compost collection. Recycling also puts the bag back into the paper supply stream, reducing the need for need virgin fiber. But composting or using bags as ground cover or weed barriers positively impacts the environment as well as it eliminates use of chemicals and plastics.

Before recycling or composting ' don't forget, paper bags are also reusable. They can be used to cover books, pack lunches, wrap gifts, create gift cards or notepads, or used as scrap paper.

How long does a paper bag take to biodegrade? How does that compare to other items?

This is an interesting statistic. Of course, how quickly something breaks down depends on the environment in which it must do so. Even fruit peels, which normally break down in just days won't break down if put inside a plastic bag in a landfill because they won't have adequate light, water, and bacterial activity required for the decay process to begin.

This chart we found at www.sciencelearn.org shows how long some common items take to biodegrade in a natural setting:

Visit their site to learn more about biodegradability and the science of how they measured the timeframes above. Factors that may affect how quickly a paper bag biodegrades include the thickness (or basis weight) of the paper and the environment in which it is expected to break down. Wetter, warmer conditions make for faster biodegradation.

Which paper bag is right for my company?

WCI offers many environmentally friendly packaging options as well as several that are bag ban compliant.

All paper merchandise bags and SOS bags manufactured at WCI are 100% recyclable and can be composted. We also offer many eco-friendly shipping bag options like the Eco-Natural® mailer, which is made with 100% recycled fibers and can be composted as well.

Please visit our website or call our sales team if you'd like help selecting a bag that will effectively package your product.

Sources:

www.twosidesna.org

www.tappi.org

www.sciencelearn.org

The company is the world’s best biodegradable plastics bags supplier. We are your one-stop shop for all needs. Our staff are highly-specialized and will help you find the product you need.

Comments

Please Join Us to post.

0