In the world of industrial manufacturing, heat treatment processes play a crucial role in enhancing the mechanical properties of metal components. Among the various methods available, bar induction hardening and tempering machines have emerged as a revolutionary solution. These machines provide efficient and precise heat treatment, offering superior strength, durability, and wear resistance to bars and cylindrical workpieces. In this article, we will explore the concept of bar induction hardening and tempering machines, their advantages, and their applications in different industries.

Understanding Bar Induction Hardening and Tempering

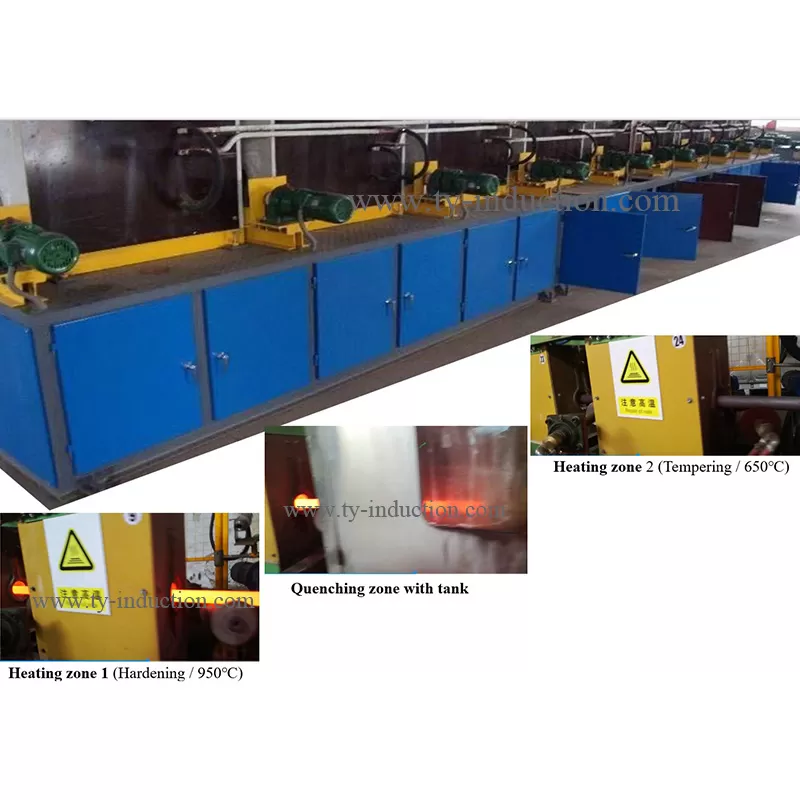

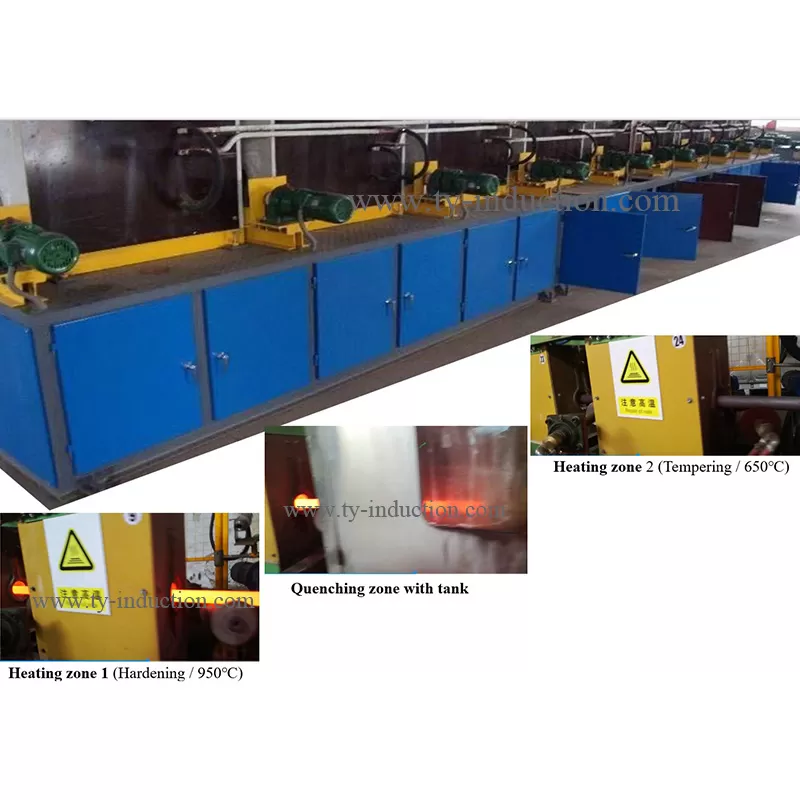

Bar induction hardening and tempering machines utilize electromagnetic induction to heat and treat bars or cylindrical workpieces. The process involves passing the bar through a series of induction coils that generate a high-frequency alternating magnetic field. This field induces rapid and controlled heating in the surface layer of the bar, followed by quenching to achieve the desired hardness. Subsequently, tempering is applied to enhance the toughness and relieve internal stresses, resulting in a well-balanced combination of hardness and strength.

Advantages of Bar Induction Hardening and Tempering Machines

Bar induction hardening and tempering machines offer several significant advantages over traditional heat treatment methods. Let's explore some of the key benefits:

Enhanced Efficiency and Productivity

By employing induction heating technology, bar induction hardening and tempering machines deliver remarkable efficiency gains. The rapid heating process reduces cycle times, allowing for higher production throughput. Moreover, the localized heating focuses energy precisely where it is needed, minimizing energy waste and optimizing resource utilization.

Superior Quality and Consistency

Consistency in heat treatment results is paramount for ensuring high-quality and reliable components. Bar induction hardening and tempering machines excel in providing exceptional consistency and uniformity in hardness and mechanical properties. The precise control over the heating and quenching process ensures consistent results across all treated bars, leading to superior product performance and longevity.

Flexibility and Adaptability

Bar induction hardening and tempering machines offer remarkable flexibility and adaptability to accommodate a wide range of bar sizes, geometries, and materials. The process can be tailored to meet specific requirements, such as varying hardening depths or selective hardening of specific sections. This versatility makes bar induction hardening and tempering machines suitable for diverse applications across industries.

Precision and Control

One of the key advantages of TY Induction bar induction hardening and tempering machine is the ability to achieve precise control over the heat treatment process. The induction coils allow for accurate temperature control and zoning, enabling targeted heating and quenching. This level of control ensures that the desired metallurgical transformations and mechanical properties are consistently achieved.

Applications of Bar Induction Hardening and Tempering Machines

Bar induction hardening and tempering machines find wide-ranging applications in various industries. Some notable examples include:

i. Automotive Industry

In the automotive sector, bar induction hardening and tempering machines are utilized for heat treating critical components such as camshafts, crankshafts, and transmission shafts. These components require high strength, wear resistance, and durability to withstand demanding operating conditions. The precise and controlled heat treatment provided by these machines ensures the desired mechanical properties, contributing to the overall performance and reliability of automotive systems.

ii. Aerospace Industry

In the aerospace industry, bar induction hardening and tempering machines are instrumental in heat treating aerospace-grade alloys used in aircraft landing gear, engine components, and structural parts. The machines' precise control over the heat treatment process allows for achieving the necessary strength, fatigue resistance, and dimensional stability required in aerospace applications.

iii. Manufacturing and Machinery

Bar induction hardening and tempering machines play a vital role in general manufacturing and machinery sectors. They are utilized for heat treating various bars used in equipment, tools, and machinery production. By enhancing the hardness and wear resistance of these bars, the machines contribute to extending their service life, reducing downtime, and improving overall operational efficiency.

Conclusion

Bar induction hardening and tempering machines have revolutionized the heat treatment process for bars and cylindrical workpieces. With their enhanced efficiency, superior quality, and precise control, these machines have become indispensable in industries such as automotive, aerospace, and manufacturing. The advantages of bar induction hardening and tempering machines, including increased productivity, flexibility, and consistency, make them a preferred choice for achieving optimal mechanical properties and performance in metal components.

By adopting bar induction hardening and tempering machines, manufacturers can elevate their production processes, produce high-quality components, and gain a competitive edge in the market. As industries continue to demand improved material performance and efficiency, these advanced machines prove to be a valuable investment for meeting those requirements. With their ability to deliver reliable and repeatable results, bar induction hardening and tempering machines are transforming the landscape of heat treatment in the manufacturing world.

Comments

Please Join Us to post.

0