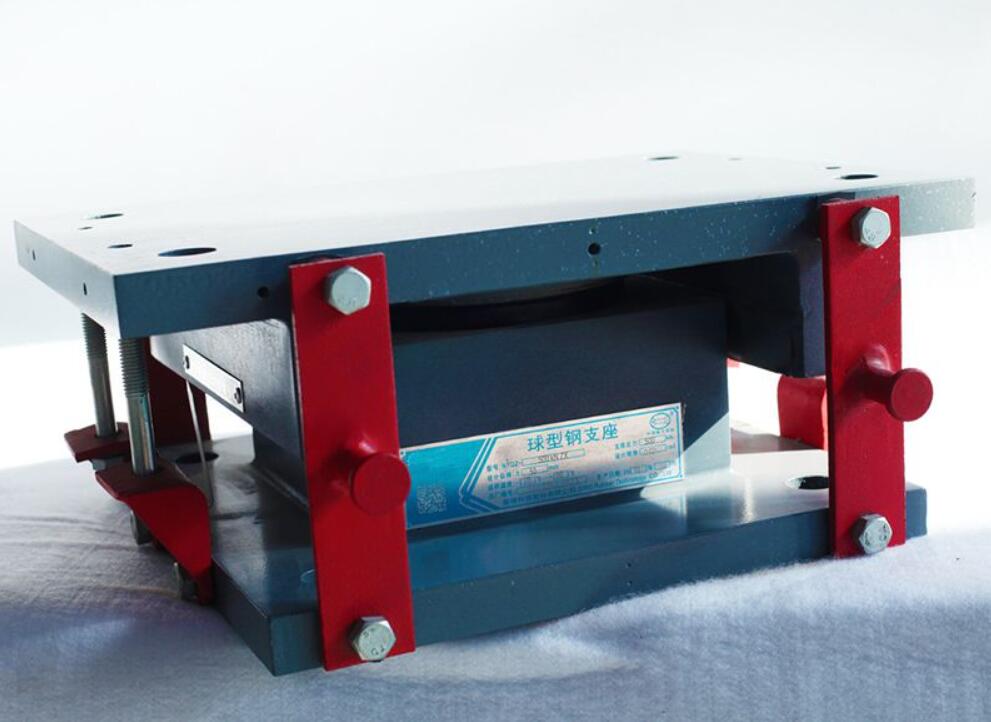

Highway infrastructure is critical to modern transportation, connecting communities and facilitating commerce across vast distances. To ensure that highways remain safe and reliable, it is essential to use high-quality components that can withstand the forces and stresses of heavy traffic and changing weather conditions. One critical component of highway infrastructure is the spherical bearing, which is used to support and accommodate movement in highway bridges and other structures.

A spherical bearing is a type of bearing that uses a pair of spherical surfaces to accommodate rotation and tilting of a component. In highway infrastructure, these bearings are typically used to support the weight of bridges and other structures, allowing them to move and flex in response to environmental factors such as seismic activity, temperature changes, and wind loads.

One of the primary functions of spherical bearings in highway infrastructure is to provide stability and safety for bridges and other structures. By allowing for movement and rotation, these bearings can help absorb forces generated by environmental factors such as earthquakes, wind loads, and temperature changes. This helps ensure that the bridge structure remains stable and secure, reducing the risk of damage or collapse.

Spherical bearings in highway infrastructure come in a variety of sizes and materials, depending on the specific application and environmental conditions. Some common materials used in highway spherical bearings include steel, bronze, and polymer composites. The choice of material will depend on factors such as load capacity, temperature range, and resistance to corrosion or other forms of degradation.

Featured content:Dancing Fountain Design: The Art of Harmonizing Water and ArchitectureWhat are the benefits of a wood slat wall?GFS Agricultural Water Storage Tanks: Enhancing Efficiency and Sustainability in FarmingHow to Properly Maintain Your Vinyl Sports FlooringGeogrid vs. Geotextile: Which Solution is Right for Soil Reinforcement?Manufacturing Process of Cold Rolled Steel CoilTypes of Outdoor Sports Court TilesIn addition to their mechanical properties, spherical bearings in highway infrastructure can also play a role in reducing noise and vibration. By providing a smooth, low-friction surface for the bridge deck to move against, these bearings can help minimize unwanted sounds and vibrations that could cause discomfort for drivers or nearby residents.

Proper installation and maintenance of spherical bearings is critical to ensuring the safety and durability of highway infrastructure. For example, bearings must be properly lubricated to prevent friction and wear, and regular inspections are needed to ensure that the bearings are functioning properly and have not been damaged by environmental factors such as corrosion or extreme weather conditions.

In recent years, advances in spherical bearing technology have led to the development of innovative new designs that offer improved performance and durability. For example, some manufacturers are now producing bearings with advanced polymer materials that offer greater resistance to corrosion and wear, as well as increased load capacity and flexibility.

Overall, spherical bearings are a critical component of safe and durable highway infrastructure. By providing stability and support for bridges and other structures, these bearings help ensure that our highways remain safe and reliable for years to come. As such, they are an important consideration for any engineer or designer working on highway infrastructure projects, and proper installation and maintenance of these bearings should be a top priority for anyone responsible for maintaining our nation's highways.Submit Your Request

Featured content:Benefits of Belleville WashersCustom Medicine Cabinets: A Perfect Blend of Functionality and StyleLED Bathroom Mirror: Illuminating Elegance and FunctionalityThe Ultimate Guide to HPMC for Tile Adhesive: Boosting Performance and QualityNail-Free Adhesive: The Ultimate Solution for Hassle-Free BondingBenefits and Uses of Hydroxy Ethyl Cellulose in Personal Care ProductsChoosing the Right Electric Security Fence

Comments

Please Join Us to post.

0