How Are Sodium Sulphide Flakes Produced and What is Their Chemical Composition?

Sodium sulphide flakes are a type of inorganic compound that is commonly used in a variety of industrial applications, from leather processing to mining. These flakes are produced through a process that involves the reaction of sodium hydroxide (NaOH) with sulphur (S). In this article, we will explore how sodium sulphide flakes are produced and what their chemical composition is.

Production Process:

The production of sodium sulphide flakes involves several steps. The first step is the reaction of sodium hydroxide (NaOH) with sulphur (S). This reaction produces sodium polysulphides, which are then further reacted with sodium hydroxide to form sodium sulphide (Na2S). The reaction can be represented by the following equation:

NaOH + S → Na2S + H2O

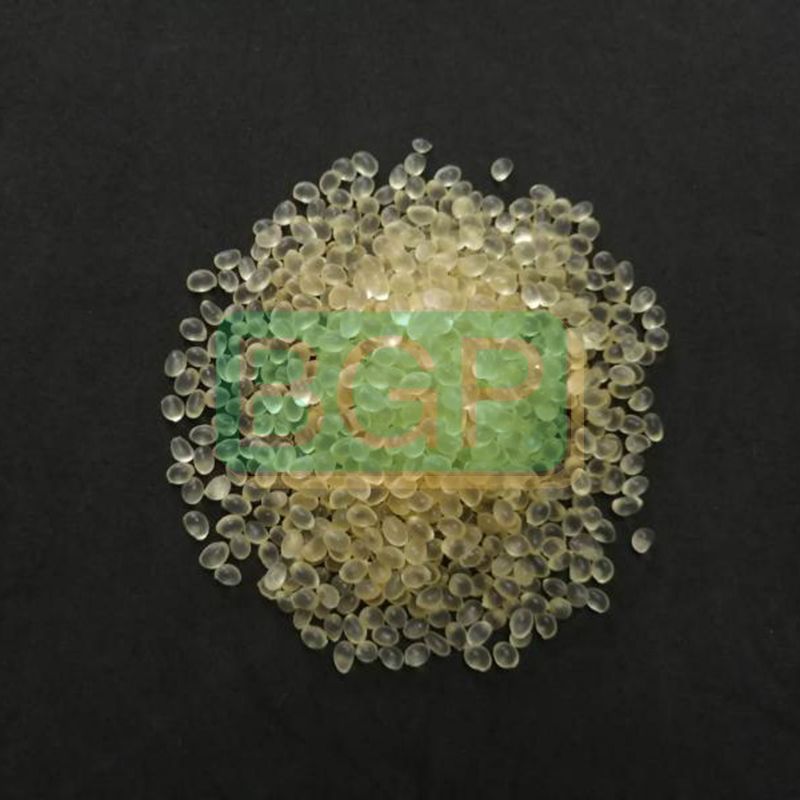

The sodium sulphide is then purified and concentrated to produce sodium sulphide flakes. The flakes are typically white or yellow in color and have a strong odor of hydrogen sulfide (H2S).

Chemical Composition:

Explore more:ChemicalsUnveiling the Impact and Solutions for Sulfur Dioxide PollutionHow PUR Hot Melt Adhesive Works: Bonding and Sealing ApplicationsAdvantages and Versatility of Redispersible Polymer Powder (RDP)Turf Latex: Enhancing the Durability and Aesthetics of Artificial Grass InstallationsHydroxypropyl Methylcellulose (HPMC): A Multifunctional Marvel in IndustriesUnlocking the Potential of Methyl Hydroxyethyl Cellulose (MHEC) in Various ApplicationsThe chemical composition of sodium sulphide flakes is Na2S. This means that each molecule of sodium sulphide contains two sodium atoms (Na) and one sulphur atom (S). The molecular weight of sodium sulphide is 78.04 g/mol.

Sodium sulphide flakes are a highly reactive compound that is soluble in water. When sodium sulphide is dissolved in water, it produces a highly alkaline solution. The alkaline nature of sodium sulphide makes it useful in a variety of industrial applications, from leather processing to mining.

Potential Hazards:

Sodium sulphide flakes are highly reactive and should be handled with care. The flakes can cause severe burns and skin irritation upon contact. They should be stored in a cool, dry place away from sources of heat and moisture. Proper protective equipment, such as gloves and goggles, should be worn when handling sodium sulphide flakes.

In conclusion, sodium sulphide flakes are an important inorganic compound that is widely used in industrial applications. The flakes are produced through a process that involves the reaction of sodium hydroxide with sulphur. The chemical composition of sodium sulphide flakes is Na2S, which is a highly reactive and soluble compound. It is important to handle sodium sulphide flakes with care and follow proper safety precautions to avoid accidents and injuries.

Featured content:DEVELOPMENT TREND OF SURFACTANT APPLICATIONWhat does ammonium sulphate do to plants?The Power of C2H2 Industrial Gas in Modern IndustriesUnlocking the Magic of Hydroxypropyl Methylcellulose: A Game-Changer in Modern IndustryBoost Your Phenol Alkylation Plant's Efficiency with Steric ConsiderationsWhat is RDP Powder Used For?What are the properties of polypropylene fiber?

Comments

Please Join Us to post.

0