Rubber seals are an essential component in many industrial and automotive applications. They are used to prevent leaks, reduce friction, and protect valuable equipment from damage. But have you ever wondered how these rubber seals work? In this article, we will explore the technology behind rubber seals and how they function to provide superior sealing performance.

What are Rubber Seals?

Rubber seals are circular rings made from various types of rubber materials. These seals are designed to fit into grooves or cavities to create a tight seal between two surfaces. They are commonly used in engines, hydraulic systems, pumps, and other machinery to prevent the leakage of fluids or gases.

How Do Rubber Seals Work?

Rubber seals work by creating a barrier between two moving or stationary surfaces. When a rubber seal is compressed between two surfaces, it fills the gaps and irregularities to prevent the passage of fluids or gases. This sealing action is achieved through the deformation of the rubber material, which allows it to conform to the shape of the surfaces it is in contact with.

The key to the effectiveness of rubber seals lies in their elasticity and resilience. Rubber materials have the ability to recover their original shape after deformation, allowing them to maintain a tight seal under varying conditions of temperature, pressure, and motion. This flexibility makes rubber seals an ideal choice for sealing applications where reliability is crucial.

Types of Rubber Seals.

There are various types of rubber seals available, each designed for specific applications and environments. Some common types of rubber seals include:

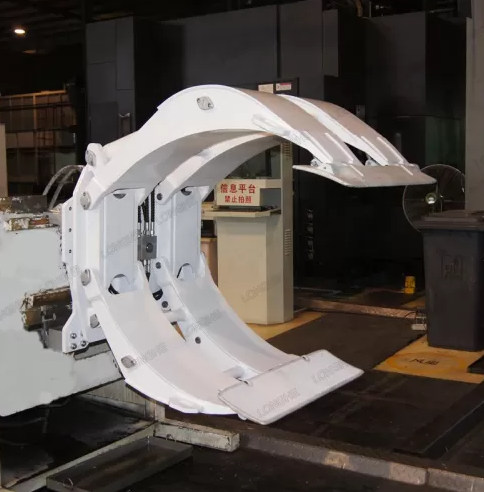

Featured content:How do I choose the right sealing gasket?Mastering Efficiency and Reliability: The Ultimate Guide to Vertical Slurry PumpsThe Comprehensive Guide to Gravel PumpsThe Benefits of Custom BearingsTypes of Forklift AttachmentsAdvantages of Using Cylindrical Roller BearingsThe Ultimate Guide to Triplex Mud Pumps1. O-Rings: O-Rings are circular seals with a round cross-section. They are used in a wide range of applications due to their versatility and ease of installation.

2. Lip Seals: Lip seals, also known as oil seals, are used to prevent the leakage of fluids in rotating shafts. They have a lip that contacts the shaft to create a barrier against the passage of liquids or gases.

3. Gaskets: Gaskets are flat seals used to create a seal between two stationary surfaces. They are commonly used in engines, pumps, and pipelines to prevent leaks and maintain pressure.

Maintaining Rubber Seals.

To ensure the optimal performance of rubber seals, it is important to conduct regular maintenance checks and replace worn-out seals as needed. Over time, rubber seals may deteriorate due to exposure to heat, chemicals, and mechanical stress. By replacing worn-out seals promptly, you can prevent leaks and avoid costly downtime.

In conclusion, the technology behind rubber seals is simple yet effective. By understanding how rubber seals work and choosing the right type of seal for your application, you can ensure reliable performance and longevity. If you have any questions about rubber seals or are looking for a supplier, feel free to contact us for more information.

Remember, maintaining your rubber seals is essential for preventing leaks and ensuring the smooth operation of your machinery. So don't hesitate to reach out to us for all your sealing needs. Contact us today to find the right supplier for your rubber seal requirements.

For more News of Rubber Seals, oil seal manufacturing, Hydraulic Cylinder Piston Sealinformation, please contact us. We will provide professional answers.

Featured content:Unveiling the Power of Mounted Workover Rigs: Revolutionizing Oilfield OperationsThe Core Function of Slurry Pump ImpellersWhat Does Surface Finishing Process Include?Which is better CV joints or universal joints?Where is tyre coupling used?How to Achieve Gear Coupling ReliabilityAre Photocatalyst Filters Safe for Indoor Air Purification?

Comments

Please Join Us to post.

0