Modify: Mar. 22, 2023

If you are looking for more details, kindly visit china engine oilseal manufacturer.

Oil seal is the customary name of general seals, which is simply the seal of lubricating oil. It is used to seal grease (oil is a common liquid substance in the transmission system, also refers to the general meaning of liquid substances) mechanical components, it will drive parts in need of lubrication and output parts of isolation, so as not to let lubricant leakage. Static and dynamic seals (general reciprocating motion) are called oil seals with seals. The representative form of oil seal is TC oil seal, which is a double lip oil seal with self-tightening spring completely covered by rubber. Generally speaking, oil seal often refers to this TC skeleton oil seal.

Common materials for oil seals are: Nitrile rubber (NBR), fluorine rubber(FKM), silicone rubber, acrylic rubber, polyurethane, polytetrafluoroethylene and so on.

1. NBR

It has good heat resistance, wear resistance, resistance to various lubricants, greases, oil and gas mixtures, suitable for temperature - 30 - 120 degrees Celsius, but can no longer be used in phosphate hydraulic oil and gear oil containing extreme pressure additives, stable performance in gasoline and mineral oil with low aniline point.

2. Polyacrylate rubber (ACM)

Excellent oil and heat resistance, abrasion resistance, ozone resistance, ultraviolet radiation resistance, especially extreme pressure fluid containing lubricants, gear oil, motor oil, oil series hydraulic oil, etc., suitable for - 30 - 150 degrees Celsius range of work.

3. Fluororubber (FPM)

Aging resistance, heat resistance, oil resistance, almost applicable to all lubricants, fuel oils, gasoline, oil containing extreme pressure additives is not easy to harden, but cold resistance, high temperature wear resistance is poor, compression deformation is large, suitable for temperature - 20 ~ 250 degrees Celsius.

4. silicone rubber

It has outstanding resistance to high and low temperatures, can be used at 150 degrees Celsius for a long time without performance change, can be used at 200 degrees Celsius for 10,000 hours continuously, and can maintain its unique use flexibility, ozone resistance and weather resistance in the operating temperature range of - 70-260.

5. Teflon

It has outstanding chemical stability, thermal stability, friction reduction and self-lubrication. Its pyrolysis temperature is over 400. Therefore, it can work normally in the temperature range of - 200 - 300 degrees Celsius. Except for free fluorine and alkali metals, it has excellent corrosion resistance to chemicals, solvents, hydroxides and acids.

Nitrile butadiene rubber (NBR) and fluorine rubber (FBR) are widely used oil seals. The former has low cost, but its temperature resistance and sealing performance have been improved obviously, but the cost is higher, and it still has some bad common characteristics of ordinary rubber materials, such as poor wear resistance, short service life, especially sensitive to the eccentricity of the shaft, etc. Leakage phenomenon is still widespread. PTFE oil seal is a product with high technology content, which is the direction of oil seal development in the future.

Attention:

When choosing the material of oil seal, the compatibility of material to working medium, the adaptability to working temperature range and the ability of lip edge to follow the rotating axis at high speed must be considered. Generally, the temperature of lip edge is higher than that of working medium at 20-50 C. Attention should be paid to the selection of oil seal materials. The working range of oil seals is related to the materials used in oil seals: NBR, ACM, FPM and NBR.

For more information, please visit china engine oilseal supplier.

Featured content:How do I select the right size of mini ball valve for my project?Welded Lamination: Exploring the Advancements and ApplicationsWhat is the difference between angular contact bearing and ball bearing?Advantages of Truck Mounted Workover RigsWhere are the Key Applications for Slurry Pumps in Wastewater Treatment Systems?What is hydraulic directional control valve?Natural Gas Y Strainer: Enhancing Efficiency and Safety in Gas Supply Systems

Product Description

Oil seals are used for automobile engines and geared motors, and are designed mainly to prevent oil leakage from the end of a rotating shaft, or dust intrusion from the outside air.

Oil seals serve to prevent the leakage not only of lubricants, but also water, chemicals, and gas from "gaps" in machinery. Oil seals also serve to prevent the intrusion of dust, soil and sand from the outside air.

Oil seals are indispensable sealing devices and are used in various fields, including automobiles, aircraft, boats and ships, railroad vehicles, construction machinery, farm machinery, petrochemical plants, and electrical home appliances.

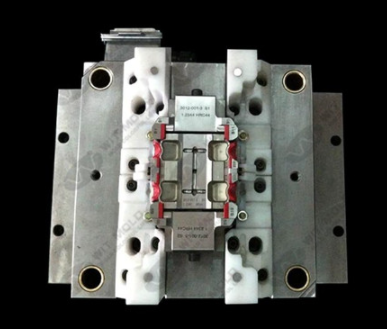

Detailed Photos

Product Parameters

Item Name

Rubber Oil Seal

Material

NBR FKM etc

Hardness

Shore A 40-90

Color

Black, red, blue, brwon etc

Size

Diameter from 10mm to 2500mm

Package

10 or 20 pcs per paper, then in carton

Production time

10-15days

Sample

Free

Certifications

Packaging & Shipping

Company Profile

Shenzhou Sanshi Rubber Co., Ltd.(previously known as Shenzhou General Machine Tool Accessories Factory), as one of the first private enterprise getting the state manufacturing permit, was founded in 1981.Under the guide of unceasing innovating, our factory has put out many products up to high world lever .Our seal parts and machine operating pieces with "Sanshi" brand have enjoyed great reputation at home and abroad.

Main products.

Besides oil seal, we also produce customized rubber parts, o-seal ring, PU parts, customized plastic and nylon parts.

Our Advantages

1. Various material.

2. We are direct factory, so small order quantity is acceptable and lots of samples are free.

3. There are about 8000 sets of moulds are free.

4. Our factory locates in the north of China, the cheaper labor cost brings us lower production cost.

5. With more than 30-year experience, we could supply you suitable solutions.

Want more information on o ring kit boxes supply? Feel free to contact us.

Comments

Please Join Us to post.

0