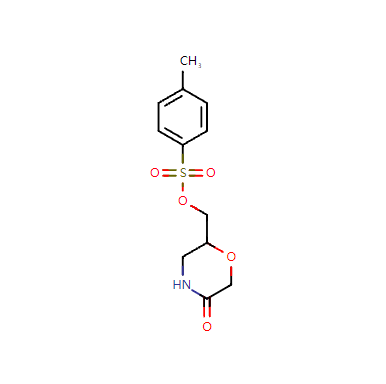

Styrene Acrylate Copolymer (SAC) is a type of copolymer made by polymerizing styrene and acrylate monomers. This copolymer is widely used in various industries, including coatings, adhesives, sealants, and construction materials. Let's discuss the mechanism of its formation and its effects in different applications:

Mechanism of Styrene Acrylate Copolymer Formation:

Monomer Selection:

Styrene and acrylate monomers are selected as they can copolymerize to form a stable and versatile polymer.

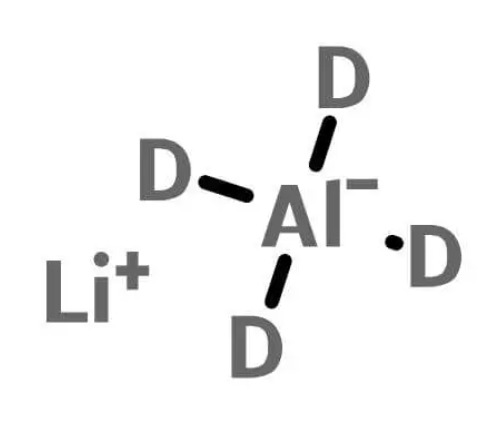

Free Radical Copolymerization:

The copolymerization process involves free radicals, which are highly reactive species. Initiators, often peroxides or azo compounds, generate free radicals that initiate the polymerization of both styrene and acrylate monomers.

Copolymerization Kinetics:

The relative reactivity of styrene and acrylate monomers determines the composition of the copolymer. The reaction kinetics and conditions are adjusted to achieve the desired properties of the final copolymer.

Random Copolymer Structure:

The copolymer typically has a random arrangement of styrene and acrylate units along the polymer chain. The distribution of monomer units influences the copolymer's properties.

Effects of Styrene Acrylate Copolymer:

Adhesion and Cohesion:

SAC is known for its excellent adhesion properties. It forms strong bonds with various substrates, enhancing the cohesion of materials in applications like adhesives and sealants.

Explore more:ChemicalsHow is EVA Hot Melt Adhesive Applied?How is Copper Sulphate Used on Plants?What Are the Benefits of Using PP Fibers in Concrete?Revolutionizing Cancer Treatment: Unveiling the Promising Applications of PROTACsTHE POWER OF VITAMIN C: A COMPREHENSIVE GUIDE TO ITS BENEFITSQuestions about You Should Know about HPMCFlexibility and Toughness:

The incorporation of acrylate units imparts flexibility and toughness to the copolymer. This makes SAC suitable for applications where a balance between flexibility and strength is required, such as in coatings and elastomers.

Weather Resistance:

Styrene Acrylate Copolymer is often used in exterior coatings due to its resistance to weathering and UV degradation. This makes it suitable for outdoor applications where long-term exposure to sunlight and environmental conditions is expected.

Emulsion Stability:

SAC is commonly used in emulsion polymerization processes to create stable dispersions. The copolymer stabilizes the emulsion, preventing phase separation and allowing for uniform coatings and paints.

Water Resistance:

The hydrophobic nature of styrene units contributes to the water resistance of SAC. This property is beneficial in applications such as water-based paints and coatings.

Film Formation:

SAC can form smooth and continuous films, making it valuable in applications like paint, where an even coating with good coverage is essential.

Cost-Effective Solution:

Styrene and acrylate monomers are often more cost-effective than some alternative monomers, making SAC a economically viable option for various applications.

In summary, Styrene Acrylate Copolymer is a versatile material with a range of desirable properties, including adhesion, flexibility, weather resistance, and emulsion stability. Its synthesis involves free radical copolymerization of styrene and acrylate monomers, resulting in a copolymer with a random arrangement of units along the polymer chain. The specific properties and applications of Longou SAC can vary based on the copolymer composition and the intended use in different industries.

Featured content:Understanding the Impact of Iron Oxide on ConcreteWhat is the purpose of a surfactant?Is Hydroxyethyl Cellulose the Best Construction Additive?What is the difference between acrylic paint and acrylic emulsion?What are the sectors of the cosmetic industry?Revolutionizing Eco-Friendly Construction: Turf SBR Latex?What is the introduction of artificial turf?

Comments

Please Join Us to post.

0