With competitive price and timely delivery, TEPAI sincerely hope to be your supplier and partner.

### Step-By-Step Guide to Automatic Bottle Blowing.

### Step 1: Prepare the Materials.

Start by gathering all the necessary materials for automatic bottle blowing, including the plastic resin granules, molds, and any additional additives needed for the specific type of bottle you are making.

### Step 2: Set Up the Machine.

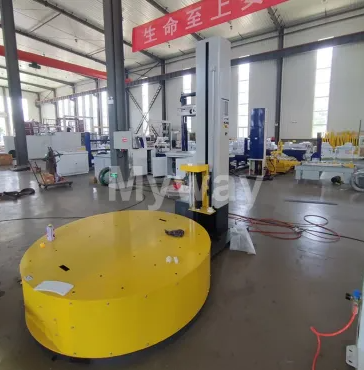

Once you have all the materials ready, it's time to set up the automatic bottle blowing machine. Make sure the machine is properly calibrated and that all components are in good working order before proceeding.

### Step 3: Load the Resin.

Carefully load the plastic resin granules into the hopper of the automatic bottle blowing machine. The amount of resin needed will vary depending on the size and shape of the bottle being produced.

### Step 4: Start the Machine.

With the resin loaded, start the automatic bottle blowing machine and allow it to warm up to the desired temperature. This will ensure that the resin is melted and ready for the molding process.

Featured content:What is the process of EPS shape molding?Is Aluminum Foil Laminating Machine Worth Investing?Revolutionizing Packaging Efficiency: EPE Foam Innovations?Ultimate Guide: Turnover Box Injection Mould Oil ExplainedRevolutionizing Blow Molding: 900ML Jerry Can MachineLights Out: Solving Led Bulb Housing Making DilemmasWhich extrusion blow moulding machine is best?### Step 5: Mold the Bottles.

Once the machine is up to temperature, the molding process can begin. The molten resin is injected into the molds, where it is shaped into the desired bottle shape. The molds are then cooled, allowing the bottles to solidify.

### Step 6: Remove the Bottles.

Once the bottles have solidified, they can be removed from the molds. Carefully extract the bottles from the molds, taking care not to damage them in the process.

### Step 7: Trim and Inspect.

After the bottles have been removed from the molds, any excess material can be trimmed off to give the bottles their final shape. Inspect each bottle for any defects or imperfections that may have occurred during the molding process.

### Step 8: Packaging.

The final step in the automatic bottle blowing process is packaging the bottles for distribution. Whether they are being shipped to a retailer or directly to consumers, make sure the bottles are packaged securely to prevent damage during transit.

By following these step-by-step instructions, you can successfully produce high-quality bottles using an automatic bottle blowing machine. With careful preparation and attention to detail, you can create a wide range of bottles for various industries and applications.

Please visit our website for more information on this topic.

Contact us to discuss your requirements of LED bulb holder making machine. Our experienced sales team can help you identify the options that best suit your needs.

Featured content:How do you operate a 600ML jerry can blow molding machine?10 Questions You Should Know about LED Bulb Housing Making SolutionHow to Choose Kraft Paper Bubble Envelope Making Machine? A Comprehensive Guide for ManufacturersKey Questions to Ask When Ordering Automatic Pet Bottle Blowing MachineIntroduction to Blow MoldingRevolutionizing Shipping: The Future of Packaging?10 Questions You Should to Know about 400 t injection moulding machine

Comments

Please Join Us to post.

0