Sandblasting is a process of using high-velocity streams of abrasive material to clean, etch, or shape surfaces. Glass beads are one of the most popular materials used for sandblasting due to their uniform size, low dust emission, and ability to produce a smooth finish on a variety of surfaces. When it comes to choosing the right size glass beads for sandblasting, there are several factors to consider.

The first factor to consider when choosing the size of glass beads for sandblasting is the size of the surface to be sandblasted. If you are working on a small surface, you can use smaller beads, whereas larger surfaces require larger beads. The size of the beads should be chosen based on the amount of surface area you need to cover.

Type of Surface to be Sandblasted

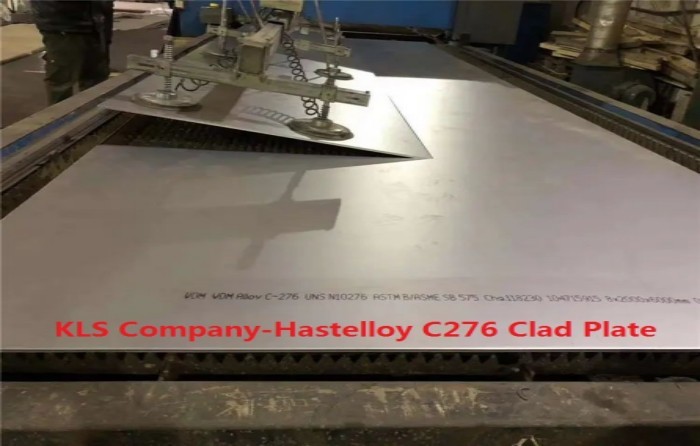

The second factor to consider when choosing the size of glass beads for sandblasting is the type of surface to be sandblasted. Different surfaces require different bead sizes to achieve the desired finish. For example, soft surfaces like wood or plastic require smaller beads, while harder surfaces like metal or concrete require larger beads.

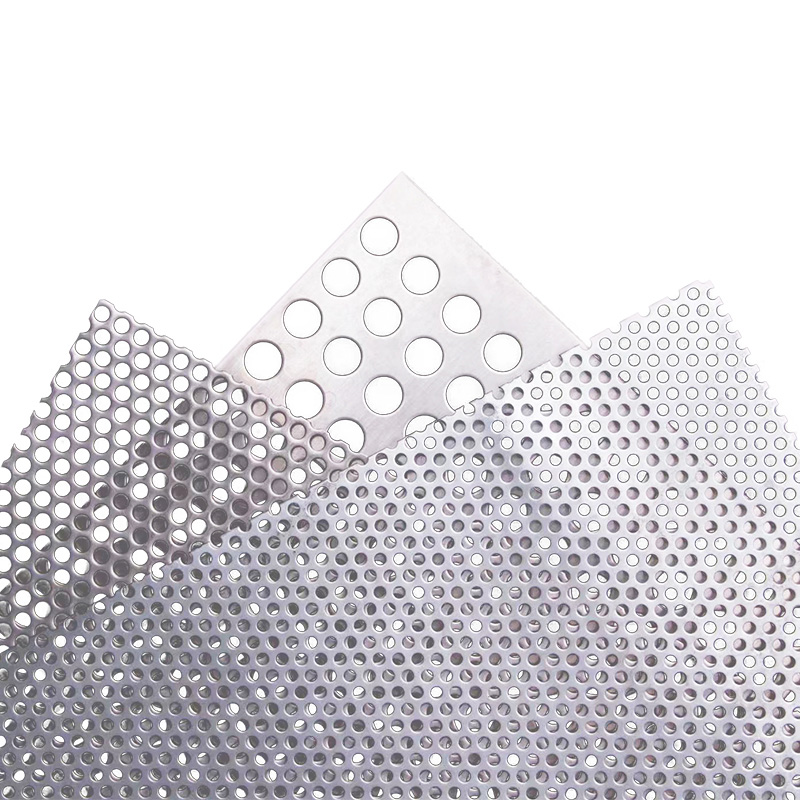

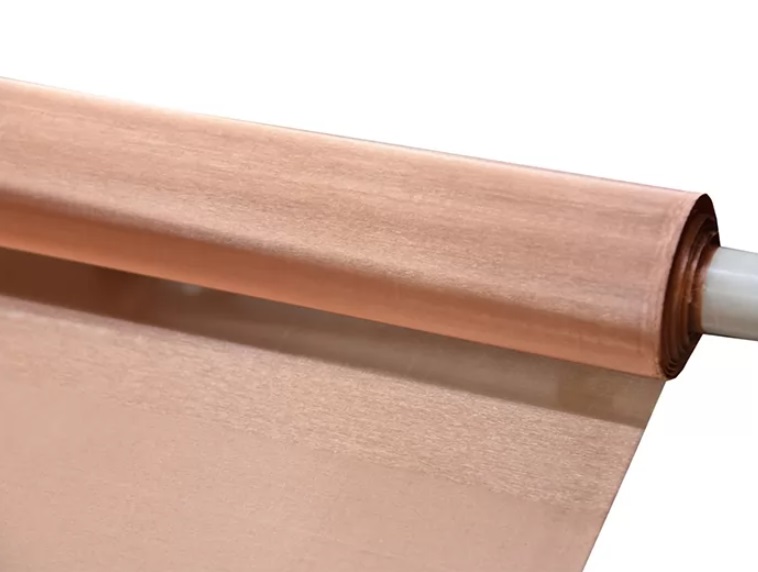

Glass Bead Blasting Media For Metal Cleaning And Polishing

Desired Finish

The third factor to consider when choosing the size of glass beads for sandblasting is the desired finish. If you are looking for a smooth finish, you should use smaller beads. Larger beads are better for a rougher finish. The size of the beads will also determine the depth of the surface you are able to etch.

Equipment being used

The fourth factor to consider when choosing the size of glass beads for sandblasting is the type of equipment being used. Different equipment has different requirements for bead size. You should consult the manufacturer’s instructions for the equipment being used to determine the best bead size.

Featured content:Stainless Steel Sheets with Vibration Non-Directional: An Aesthetic MarvelCustomized Steel Bridge Guardrail: Ensuring Safety and Efficiency in Bridge InfrastructureProcessing Spodumene by Froth Flotation for Lithium ExtractionThe basic knowledge introduction of Fiberglass Mesh FilterIs Wrought Iron an Ideal Material for Gates?Advantages of Color Coated Steel CoilsIs the Difference Between H-Beam And I-Beam?Mesh Sizes

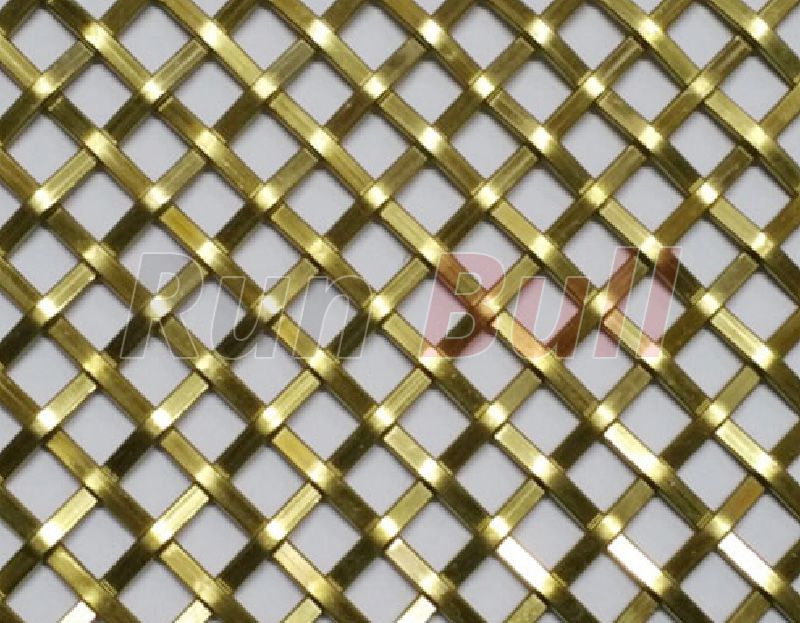

When it comes to glass bead sizes, they are typically measured in mesh sizes. A mesh size refers to the number of openings in a sieve per linear inch. The higher the mesh number, the smaller the glass beads. The following are some common mesh sizes used in sandblasting:

30-40 mesh: This size of glass beads is ideal for removing rust and paint from metal surfaces. They are also good for etching glass and stone surfaces.

40-60 mesh: This size of glass beads is ideal for cleaning and polishing aluminum and stainless steel surfaces. They are also good for creating a matte finish on metal surfaces.

60-80 mesh: This size of glass beads is ideal for removing light rust and corrosion from metal surfaces. They are also good for removing paint from softer surfaces like wood and plastic.

80-100 mesh: This size of glass beads is ideal for creating a smooth, satin finish on metal surfaces. They are also good for removing paint and light rust from delicate surfaces.

100-170 mesh: This size of glass beads is ideal for creating a fine, polished finish on metal surfaces. They are also good for removing surface blemishes from plastics and composites.

It’s important to note that these are just general guidelines and the size of glass beads you choose will ultimately depend on the factors mentioned above.

Conclusion

Choosing the right size of glass beads for sandblasting is important to achieve the desired finish and protect the surface being worked on. Factors such as the size of the surface, the type of surface, the desired finish, and the equipment being used should be taken into consideration when selecting the appropriate bead size. It is recommended to start with a smaller bead size and work your way up if needed to avoid causing damage to the surface.

Featured content:When to Use Each Type of Galvanized Wire?How to Improve Aluminum Casting Parts High Quality?What is a Low Fin Tube? Understanding its Significance in Heat ExchangersIs alloy steel better than stainless steel?What is Alloy Steel Pipe Used For? A Comprehensive GuideWhat is the Raw Material for Magnesia Carbon Bricks?Can Post Tensioning Be Used in Both New and Existing Structures?

Comments

Please Join Us to post.

0